Design and manufacture of prototypes of platforms, wedges and blocks adjusted to last to be manufactured in cork with Recreus PLA filament

- Company: Eldacorcho

- Sector: Cork industry - Footwear industry

- Material: Recreus PLA filament

- Mission: Design and manufacture of prototypes of platforms, wedges and blocks adjusted to the last for cork manufacture

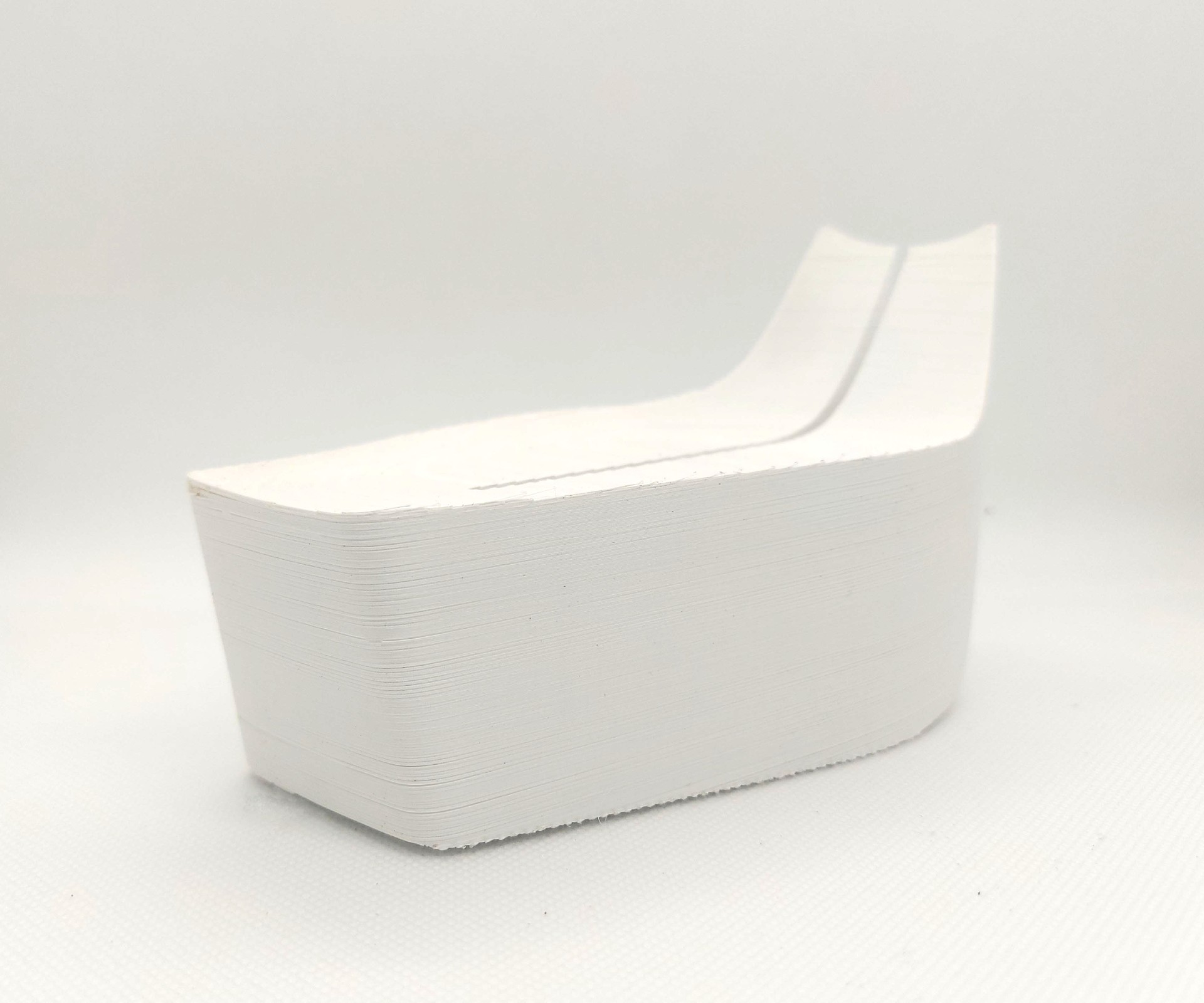

Prototype 'block' printed with Recreus' white PLA filament.

“We highly value the help and technical advice provided by Recreus as a material supplier. This is essential for us. Being able to count on the support of a trustworthy technological company that quickly solves our doubts or technical queries in this field and being effective and competent! gives us a lot of peace of mind.”

Beatriz Reyes, Eldacorcho's Design Department Manager

It is a pity that many companies are still unaware of the advantages that can be obtained by introducing 3D printing technology in their design departments. Something that, fortunately, is not the case of the Alicante-based company Eldacorcho. A national natural cork application company that was founded in 1971 in the privileged shoemaking location of the city of Elda and has seen its trajectory evolve, working on new product applications with its raw material, cork, not only for the footwear sector, but also for other areas.

The main product of Eldacorcho is aimed at the footwear sector, dedicated to the manufacture of cork platforms, wedges and blocks, among others.

PLATFORMS

Piece of footwear used to achieve greater stature at the front.

WEDGES

A piece of footwear of conventional appearance that contains an inner wedge of a certain height for the heel part.

BLOCKS

An entire piece from toe to heel that is a component of footwear worn as a fashion item that allows for greater stature.

Eldacorcho implemented 3D printing technology 10 years ago with the aim of designing and making their own prototypes, and since then they have managed to optimize their resources and improve their service and customer experience, in addition to obtaining considerable savings in time and costs when manufacturing their final molds.

“I am in charge of the design department, which currently consists of 2 people, but with projection to continue increasing thanks to the opportunities offered by 3D printing technology. With it we are growing in new sectors, outside the field of footwear, such as the ecological packaging industry, cork coatings, etc.”

Beatriz Reyes, Eldacorcho's Design Department Manager

CHALLENGE

Printing of prototypes for the manufacture of cork blocks, platforms and wedges adjusted to the last

Eldacorcho's work consists of making cork blocks, platforms and wedges adjusted to the last for the footwear sector.

'Cork 'block' manufactured by Eldacorcho for the footwear industry.

Before using 3D printing, Eldacorcho manufactured the production molds in its machining centers. The part was sent to be produced to remove the cork block and delivered to the customer to confirm the design. If, for any reason, the design was not confirmed the first time, they had to readjust the model and restart the mold production process for confirmation by the customer. But this whole process changed 10 years ago when they started using 3D printing technology instead of machining to design and manufacture these prototypes.

Now with 3D printers they first design the computer model with 3D scanning, and then print the first prototypes on the Artillery Sidewinder x1.

The last step is to check and confirm that the design fits perfectly, check the height, sole, and so on.

Once the prototype design has been confirmed by the customer, they go on to make the final production mold.

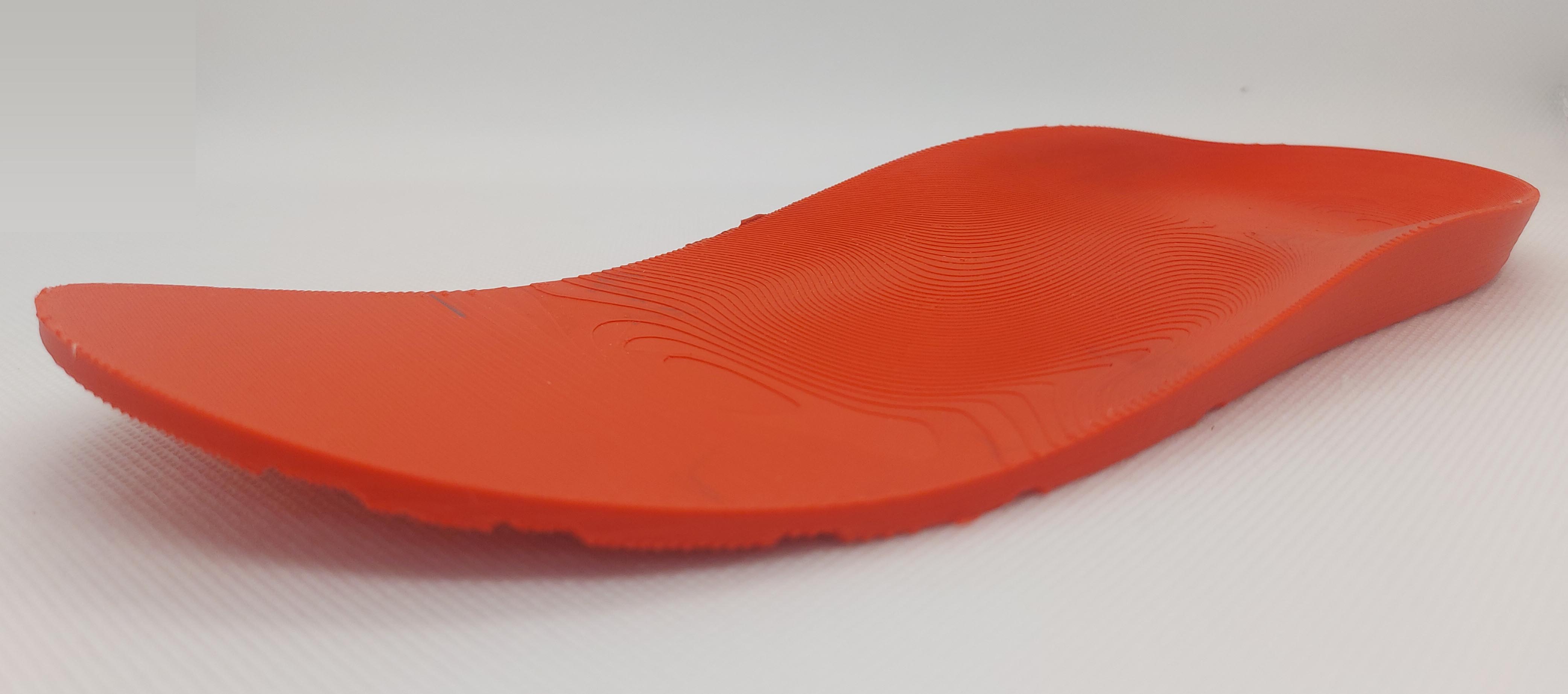

Prototype of a sole printed with Recreus' red PLA filament.

SOLUTION

PLA filament by Recreus. Easy and fast to print

To create their prototypes they print with our PLA filament in various colors in order to appreciate the different parts of the models when presenting them to their customers.

This material is ideal for this type of prototypes for the following reasons:

- Speed of printing

- Ease of printing on their printers

- Matte finish

- Variety of colors

- Very good results

- Technical consulting service with our team to improve the printing of your prototypes with our material

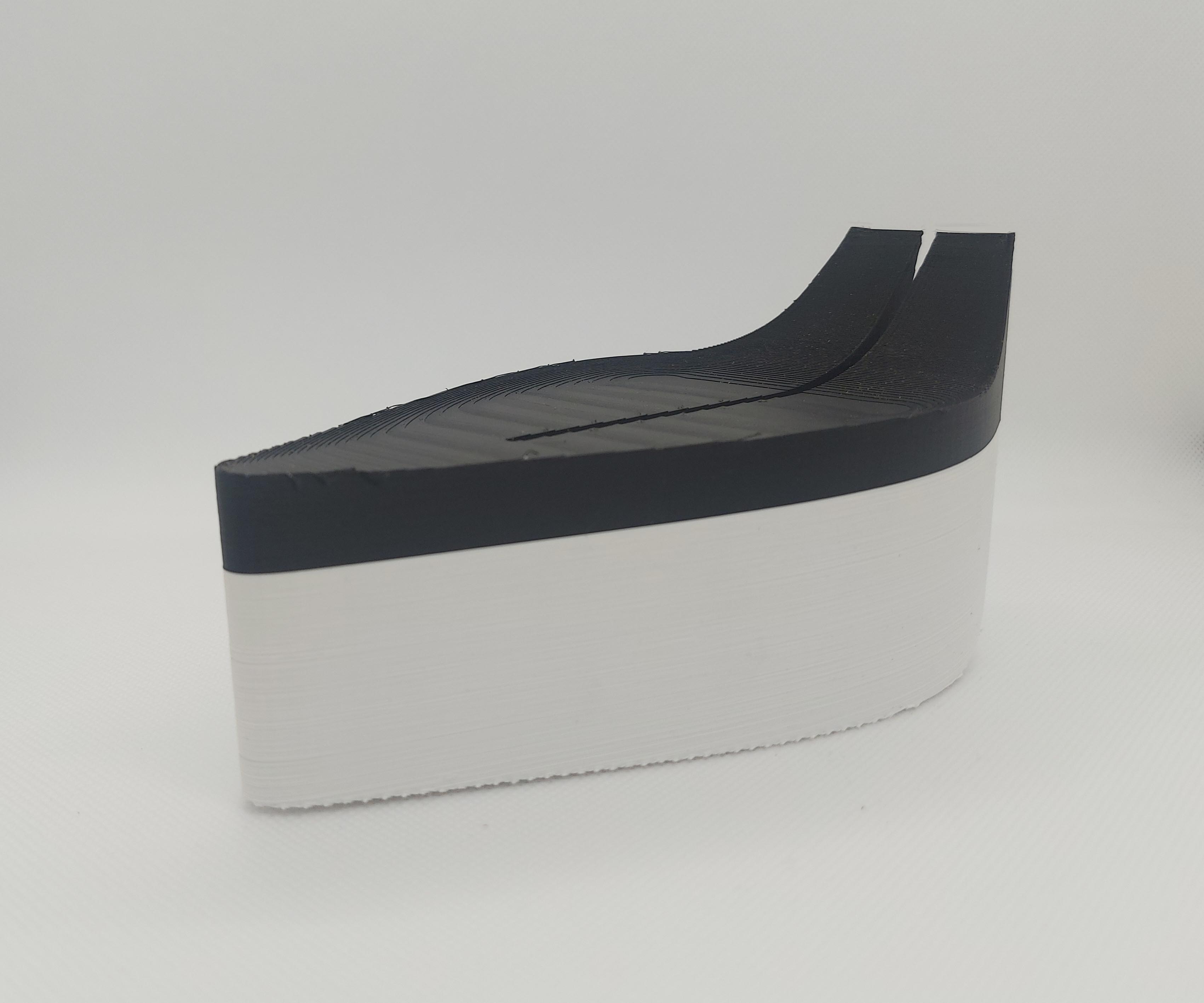

Prototype 'composite block' printed in two pieces of different colors (black and white) of Recreus PLA filament.

RESULT

Printing prototypes while optimizing your resources

- As Eldacorcho comments, if it were not for the use of this technology, they would make their production molds with the trial-and-error method. This would result in a waste of time, labor and material.

- Now, by using 3D printing, they save time in delivering the prototype to the customer, who can follow the shoe design process with the 3D prototype (lining, sole fitting, etc.) while they make the production molds. It makes their work easier and reduces your company's costs (time, material, labor).

- In addition, they highly value the help and technical advice provided by Recreus as a material supplier. This is essential for them. Being able to count on the support of a reliable technological company that helps them quickly with their doubts or technical queries in this field.

“With 3D printing we save time in delivering the prototype for confirmation by the customer, who can follow the design process of the shoe with the 3D prototype. We make their work much easier, in addition to the reduction of economic and time costs for our company.”

Beatriz Reyes, Head of Design Department at Eldacorcho

it

it  es

es en

en fr

fr de

de