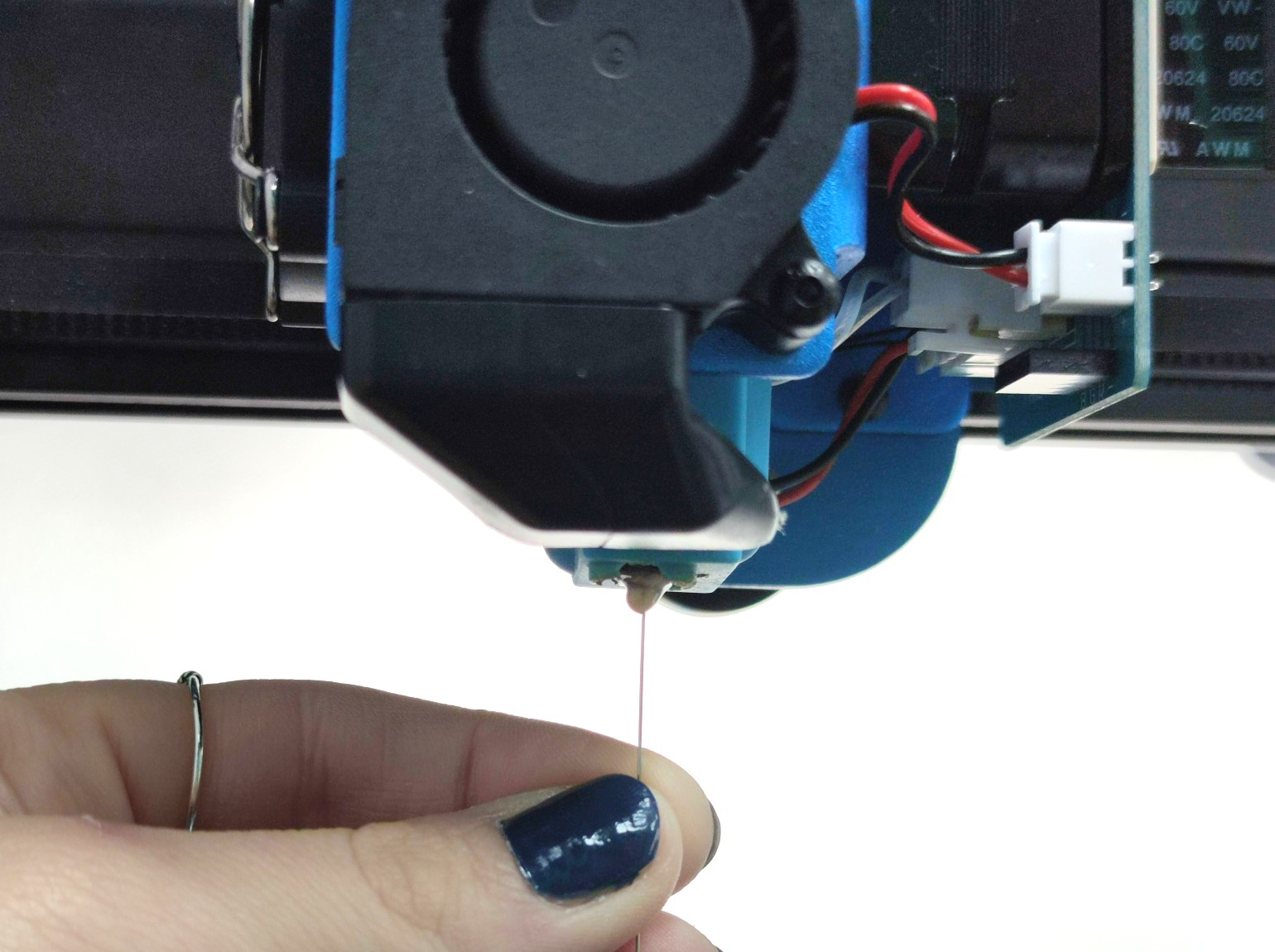

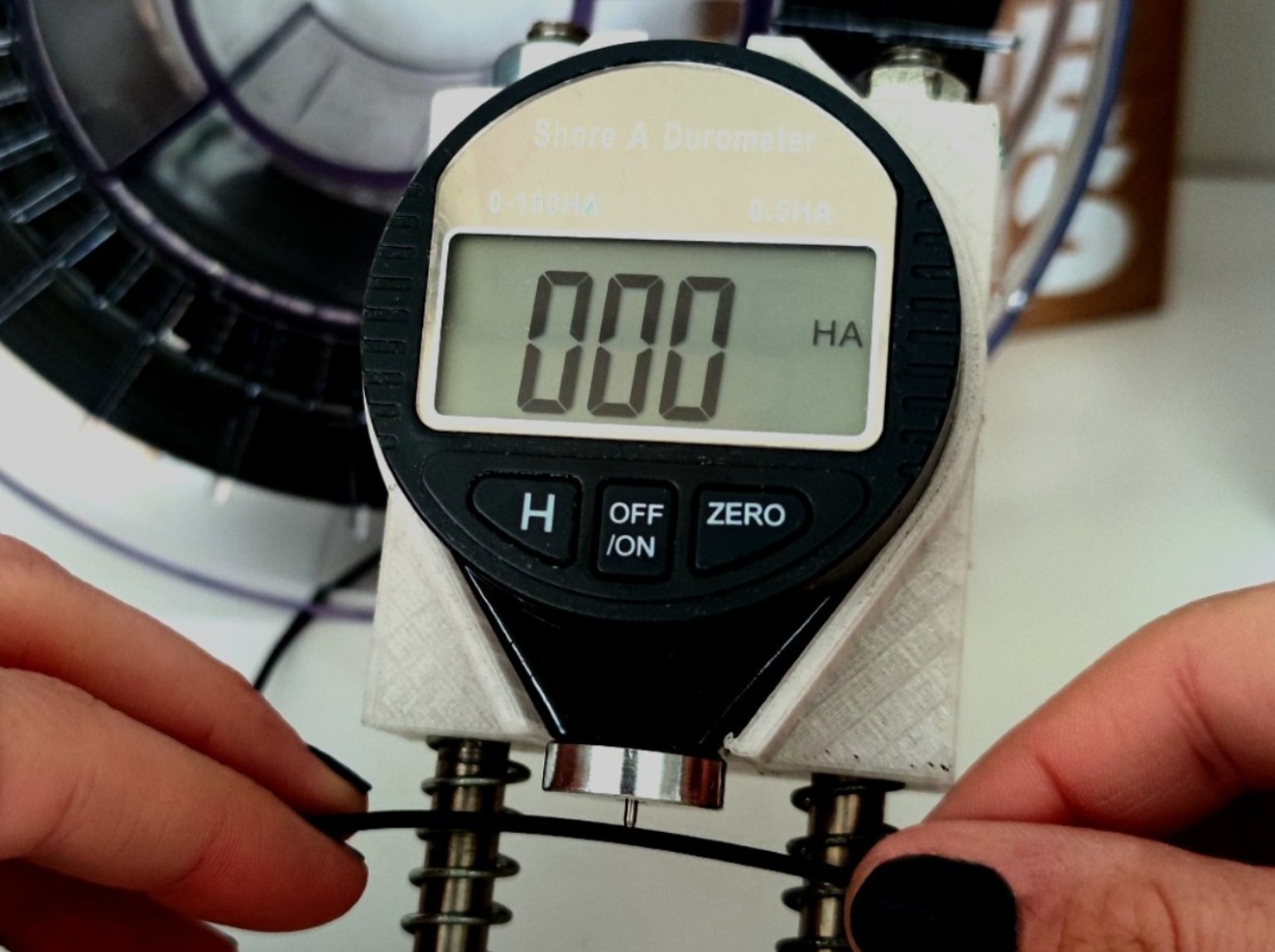

To learn about the resistivity of Conductive Filaflex (also known as specific resistance), we recommend consulting with our team. In order to determine if the material will fulfill the functions in a specific project, it's important to note that the resistance changes depending on its printing.

In order to successfully use Filaflex Conductive TPU filament in electronic applications, the electrical resistance of the circuit must be considered and keep in mind that this filament is designed for low current applications.

it

it  es

es en

en fr

fr de

de