Learn with Recreus

"-Why am I having problems when printing Filaflex elastic filament with the 'All-Metal' hotend on my 3d printer?"

This is certainly one of the most frequently asked and most common questions that our customer service department usually receives.

To help you understand this topic, we have prepared some very practical graphics that clarify the reason for the difficulty of printing this type of elastic materials, such as our Filaflex flexible filament, on a printer with an 'All-Metal' hotend, such as, for example, the hotend of the Prusa MK3S printer.

We will now analyze this combination of elements and detail the possible solutions that we recommend.

Problem of... friction!

Basically the problem can be summarized in this word: 'friction'.

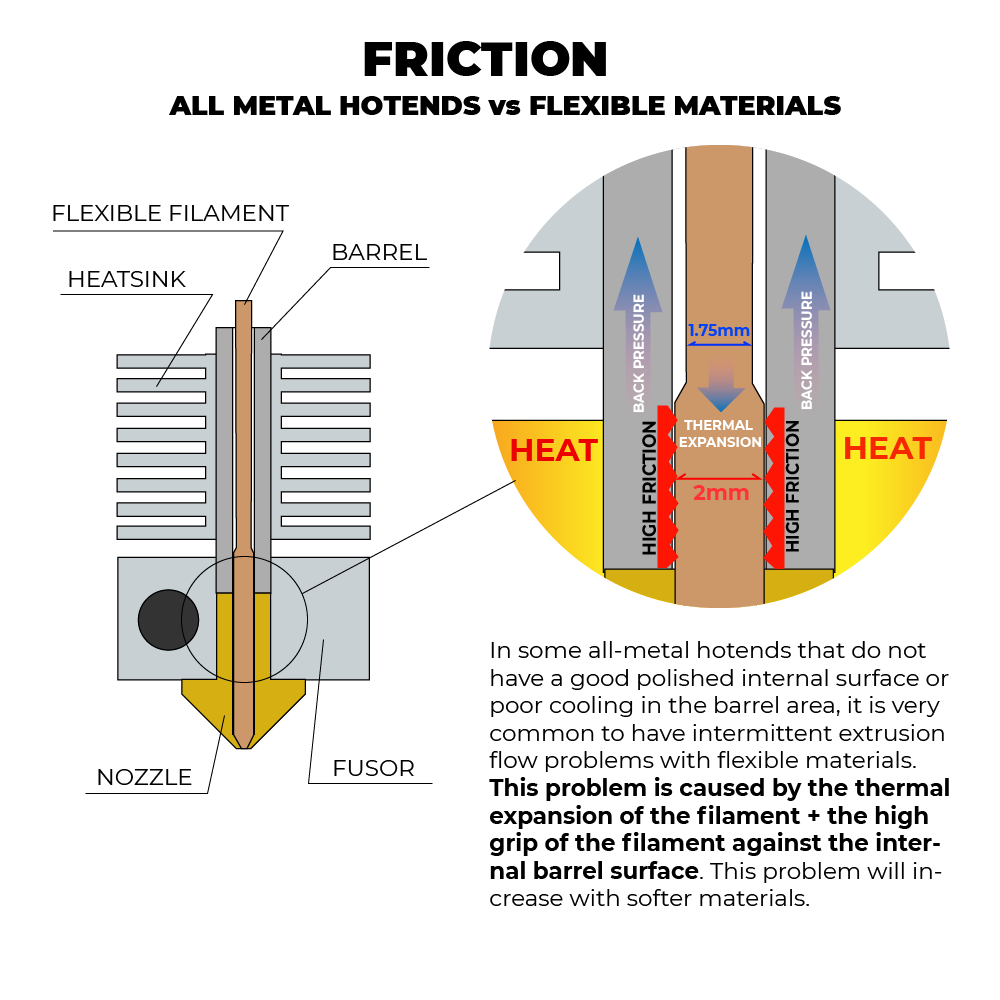

When printing a flexible TPU filament such as Filaflex in an 'All-Metal' hotend such as the Prusa MK3S printer, something very common that usually happens in this type of hotends is that it does not have a good internal polished surface or may suffer from poor cooling in the barrel area.

Therefore, during printing, we are likely to experience intermittent or discontinuous filament flow problems.

Thermal expansion

And you may ask, what exactly causes this discontinuous or intermittent flow, why does it print so badly?

This problem is caused by the thermal expansion that the filament undergoes inside the barrel and by its high predisposition to grip it to the barrel surface. This effect will increase as the filament becomes more elastic. That is, if we print with filaments with lower Shores, for example, Filaflex 70A or Filaflex 60A, the grip will be much greater and the impossibility of printing, too.

The elastic filament tends to stick to the internal, hot, metallic surface of the barrel, making it very difficult to flow and print correctly. It will produce jams and discontinuous material extrusion flows.

As the elastic filament grips or sticks to the inner, hot, metallic surface of the barrel, it is very difficult for it to flow and print properly. It will produce jams and discontinuous material extrusion flows.

Let's see in the following graph where and how this 'thermal expansion' takes place:

Recommendations

Therefore, in order to print flexible materials with this type of Hotends, we recommend, as far as possible, the following:

Keep the minimum distance between the motor pulleys and the hotend tip.

This will prevent the flexible filament from compressing or increasing its diameter inside the barrel.

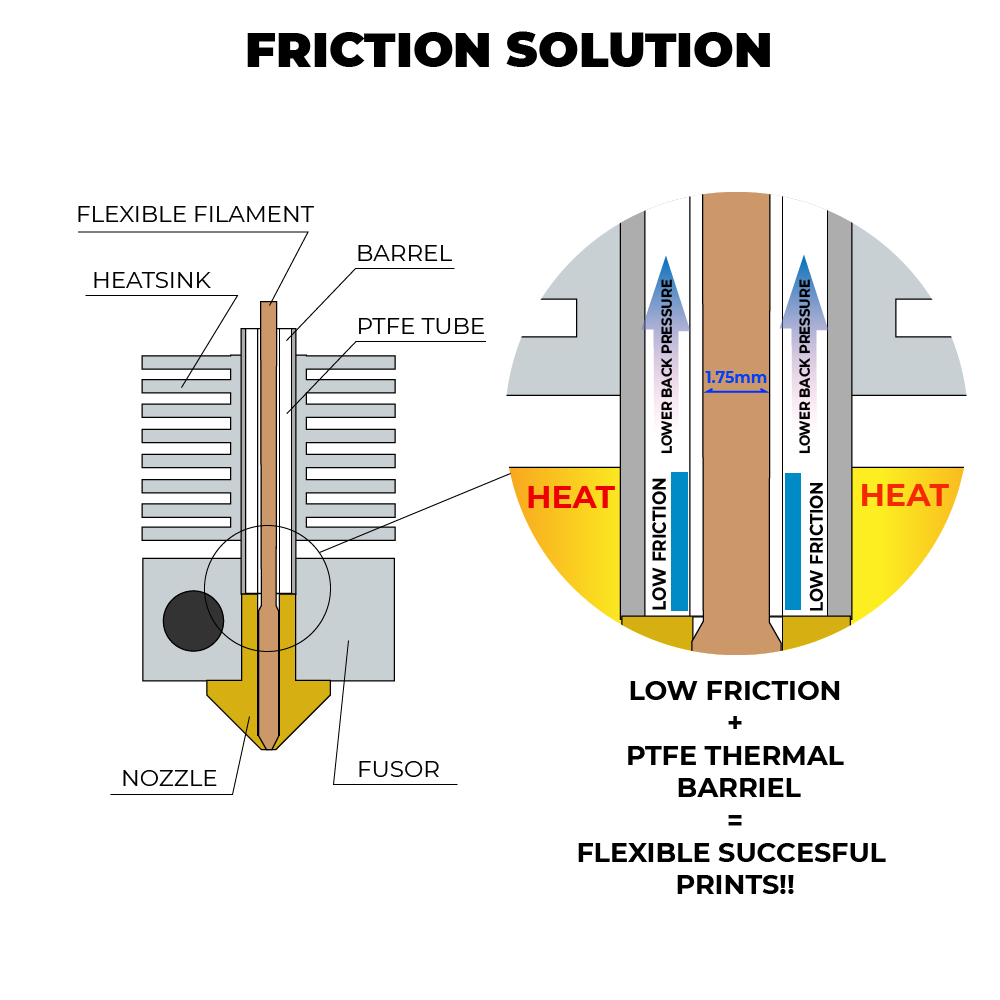

Insert a PTFE tube into the barrel of the hotend.

On the other hand, it is recommended that our hotend has a PTFE tube and that it is very well cooled. Bowden type extruders are the most problematic, but you can still use it as long as the feeding tube is made of PTFE. In extruders of this type, it is advisable to use 2.85 mm flexible filament, as it will provide more thrust force than 1.75 mm.

We can see in the following graph how by introducing a PTFE tube that reaches the front area of the Nozzle, we can solve the problem of friction of the filament with the metal wall, as well as eliminate the effect of thermal expansion that could suffer due to the effect of the high temperature in the heating block:

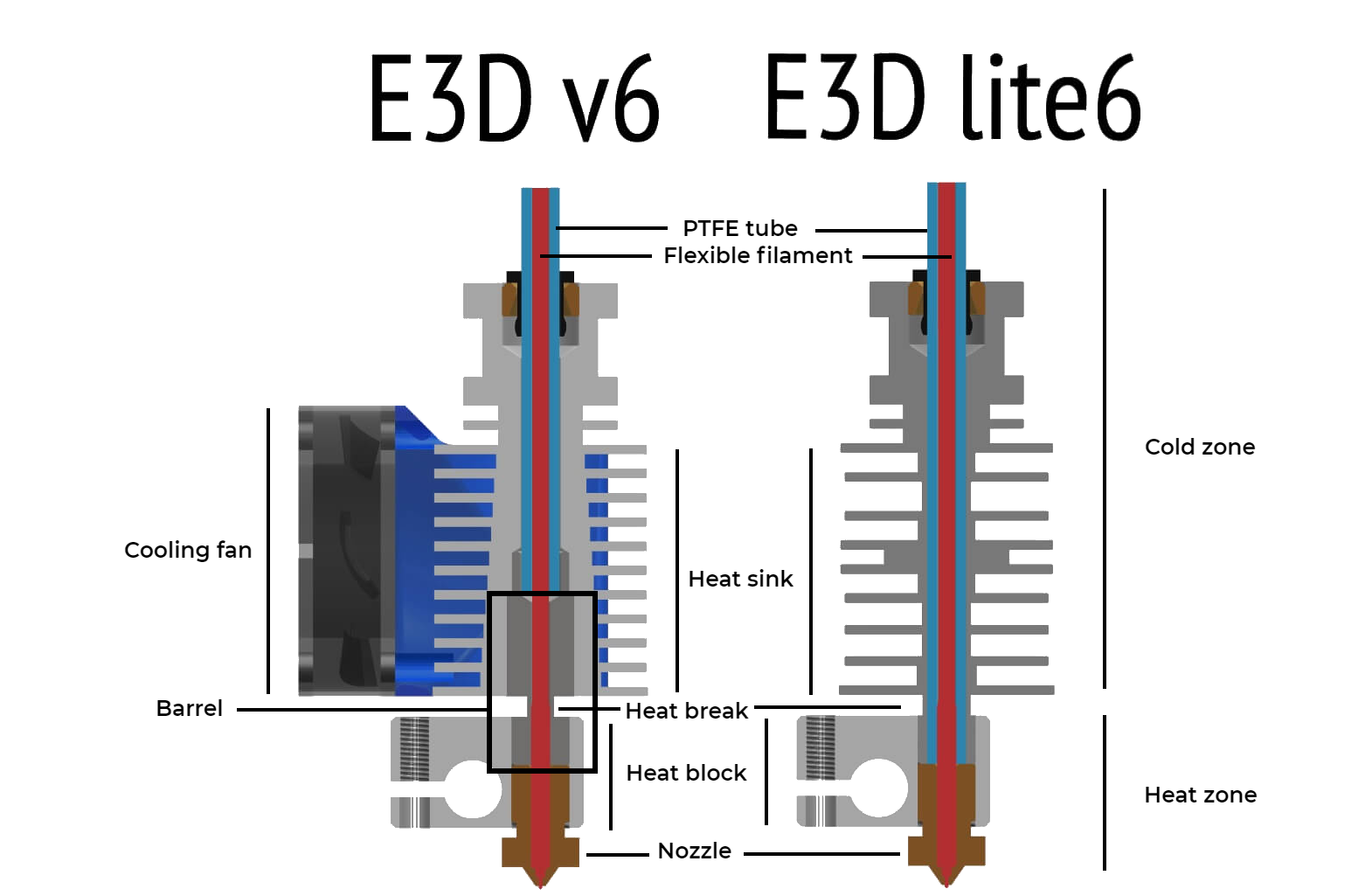

On the other hand, it is important that the PTFE tube is inserted as far as possible. In the following image we can clearly see the difference between the E3D v6 hotend and the E3D lite6.

- In the E3D v6 of 1.75 mm the tube is halfway in the heat sink area and it stops with the barrel, which leads to the flexible filament melts in the heat break area and does not perform a correct extrusion.

- In the E3D lite6 the PTFE tube goes all the way to the heater block and goes through the heatsink.

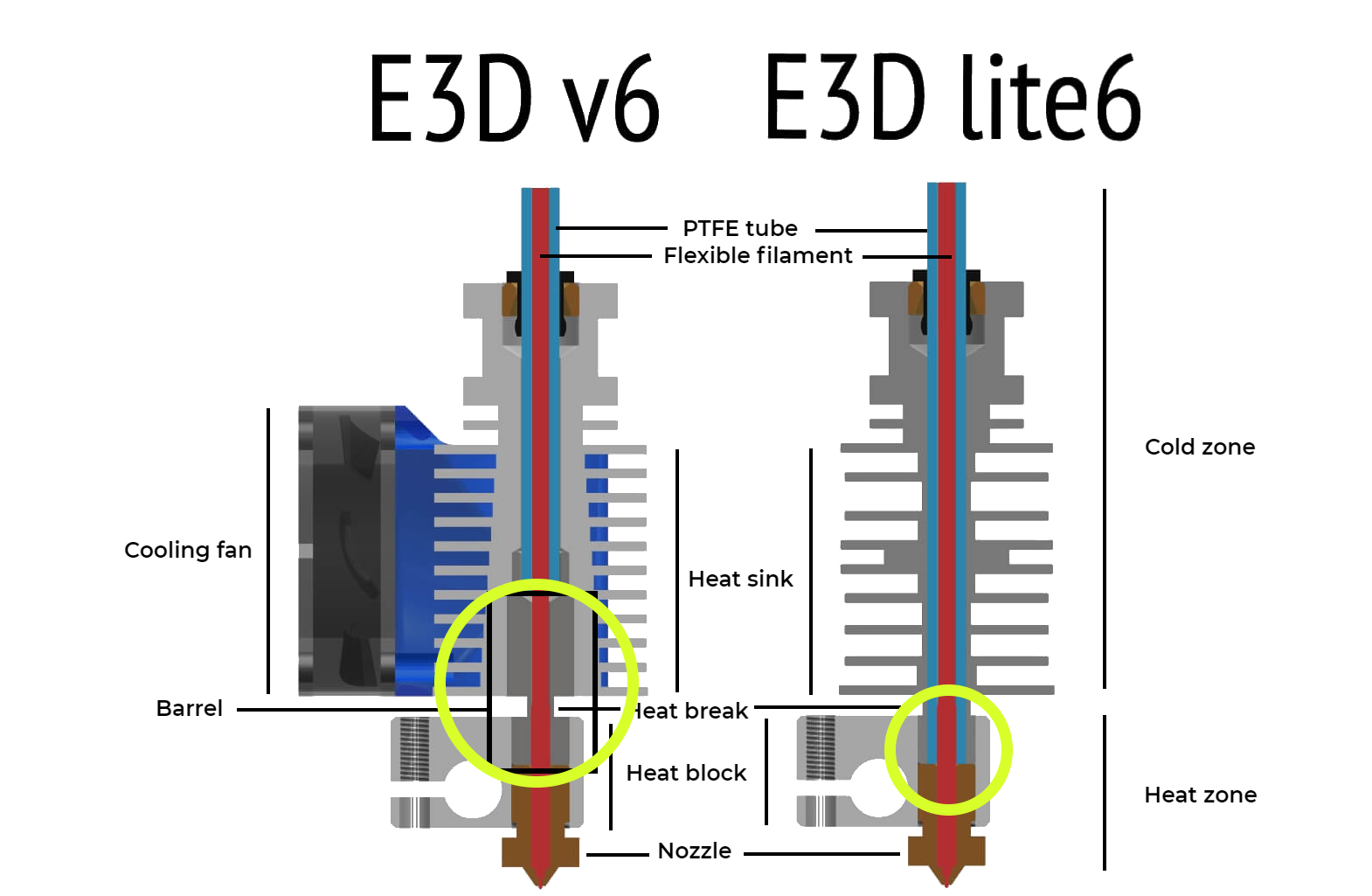

In the following graph we can see more clearly the difference between the two models, marking the comparative difference with a yellow circle:

- On the left, the E3D v6 hotend has a lack of PTFE tube extension in the lower area of the heat sink and heat break. This will cause the filament to heat up in that area upon arrival and prevent its correct extrusion.

- On the right, the E3D lite6 hotend, whose PTFE tube goes all the way to the end, protects the filament from friction, thus preventing it from undergoing thermal expansion and sticking to the inner metal surface of the barrel.

it

it  es

es en

en fr

fr de

de