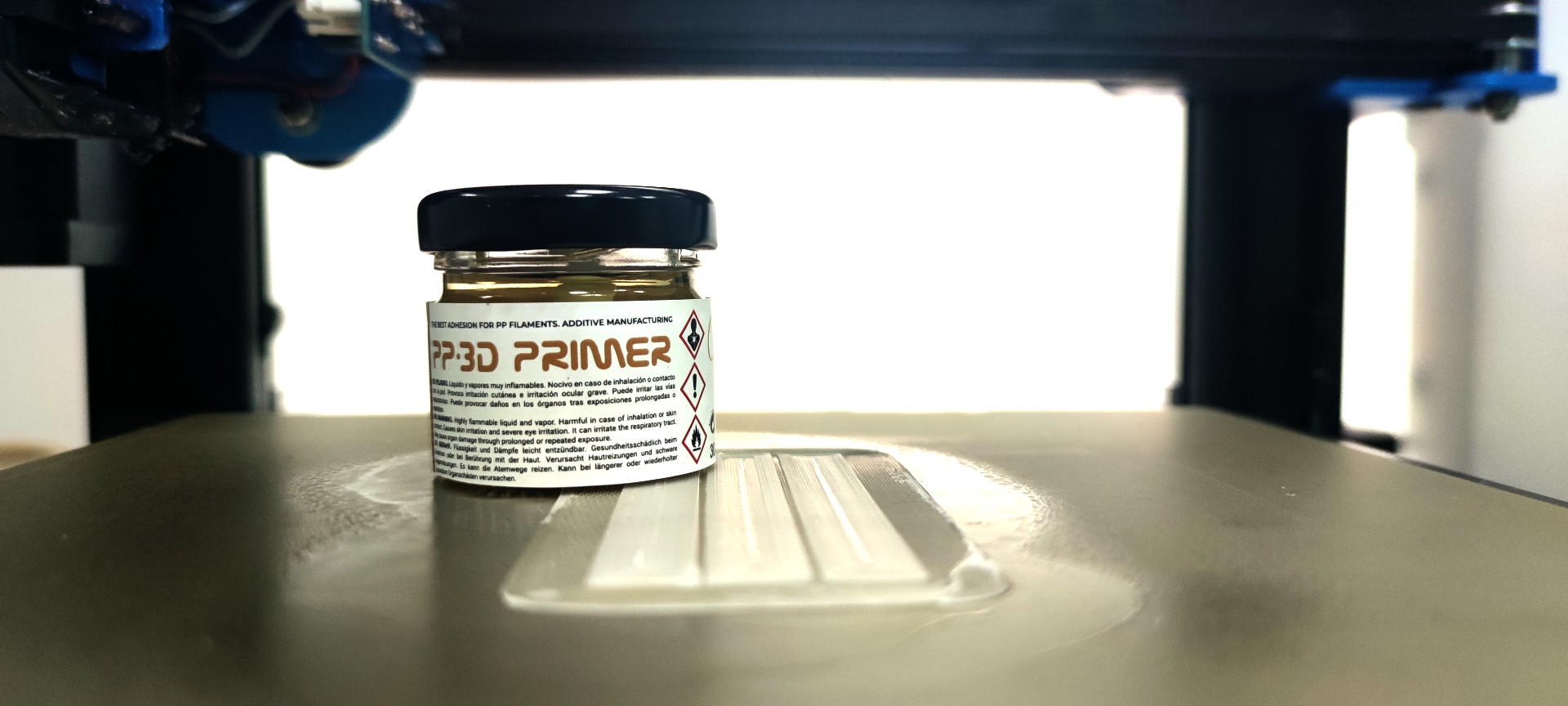

Sometimes, in spite of using the 'primer' or adhesive when printing with our PP·3D polypropylene filament, depending on the dimensions and surface of the part, it may be interesting to reinforce and improve the adhesion of the first layer to avoid 'warping'.

What is warping?

Let's remember that 'warping' is the shrinkage that occurs at the corners of the part when printing, causing them to lift and not remain firm on the print bed.

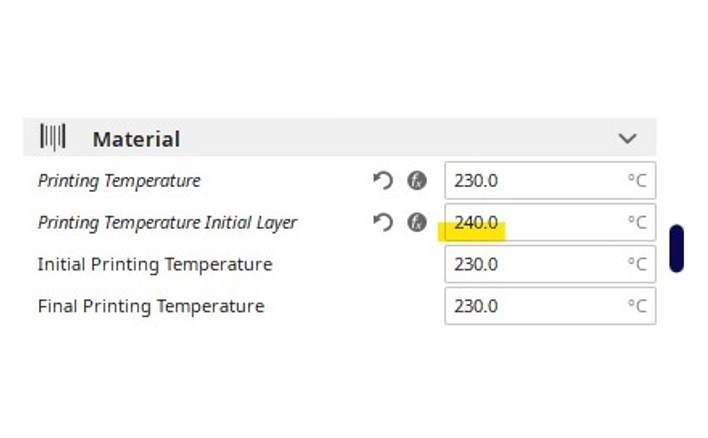

This shrinkage is caused by the temperature changes that the part undergoes, especially those with a larger surface area. Let's take into account the 230ºC of temperature coming out of the extruder depositing the filament, coming into contact with the 40ºC of the bed. All this without forgetting the cooling that occurs in the piece at room temperature. Many changes that cause the shrinkage of the material that starts from the center of the piece affecting the lifting of its corners.

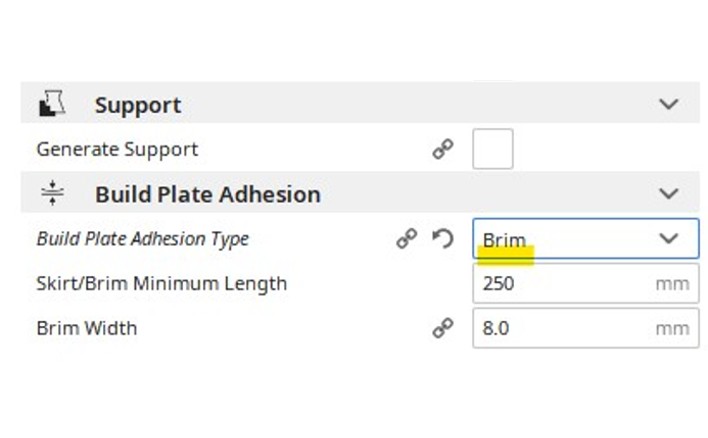

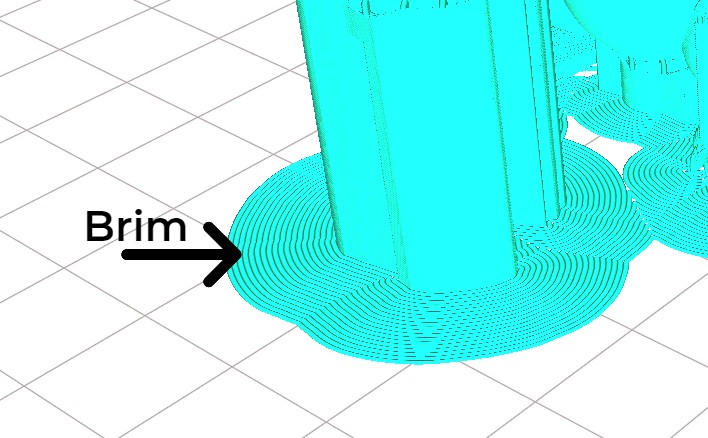

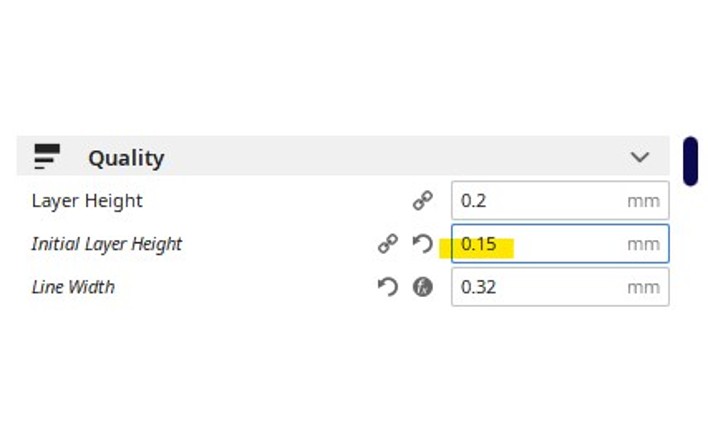

To avoid this, we tell you 3 simple settings that you can make in your printer and with which you will improve the adhesion of the PP·3D filament to the printing bed. Apart, of course, from using the 'primer' that is already included in the pack with your filament:

de

de  es

es en

en fr

fr it

it