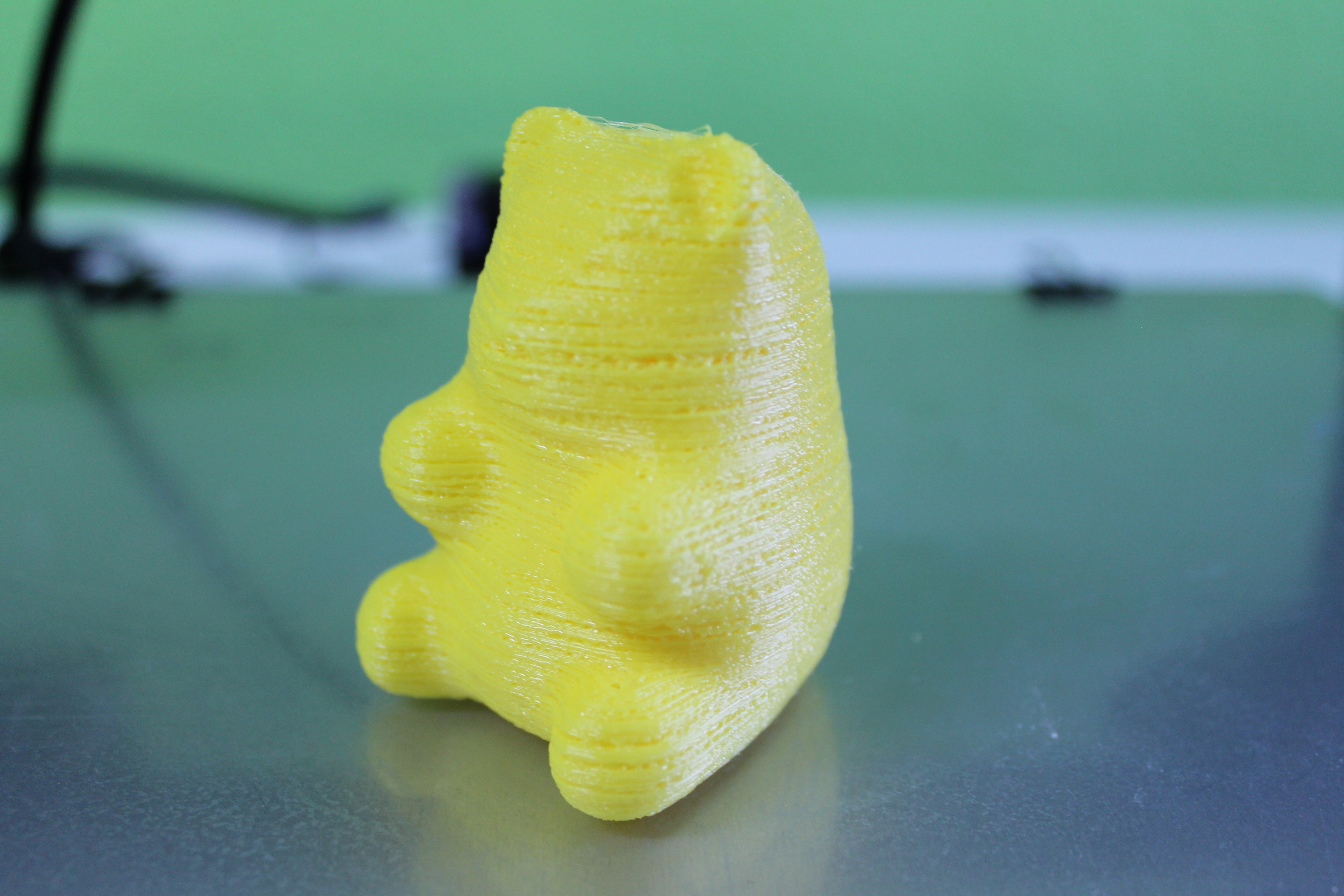

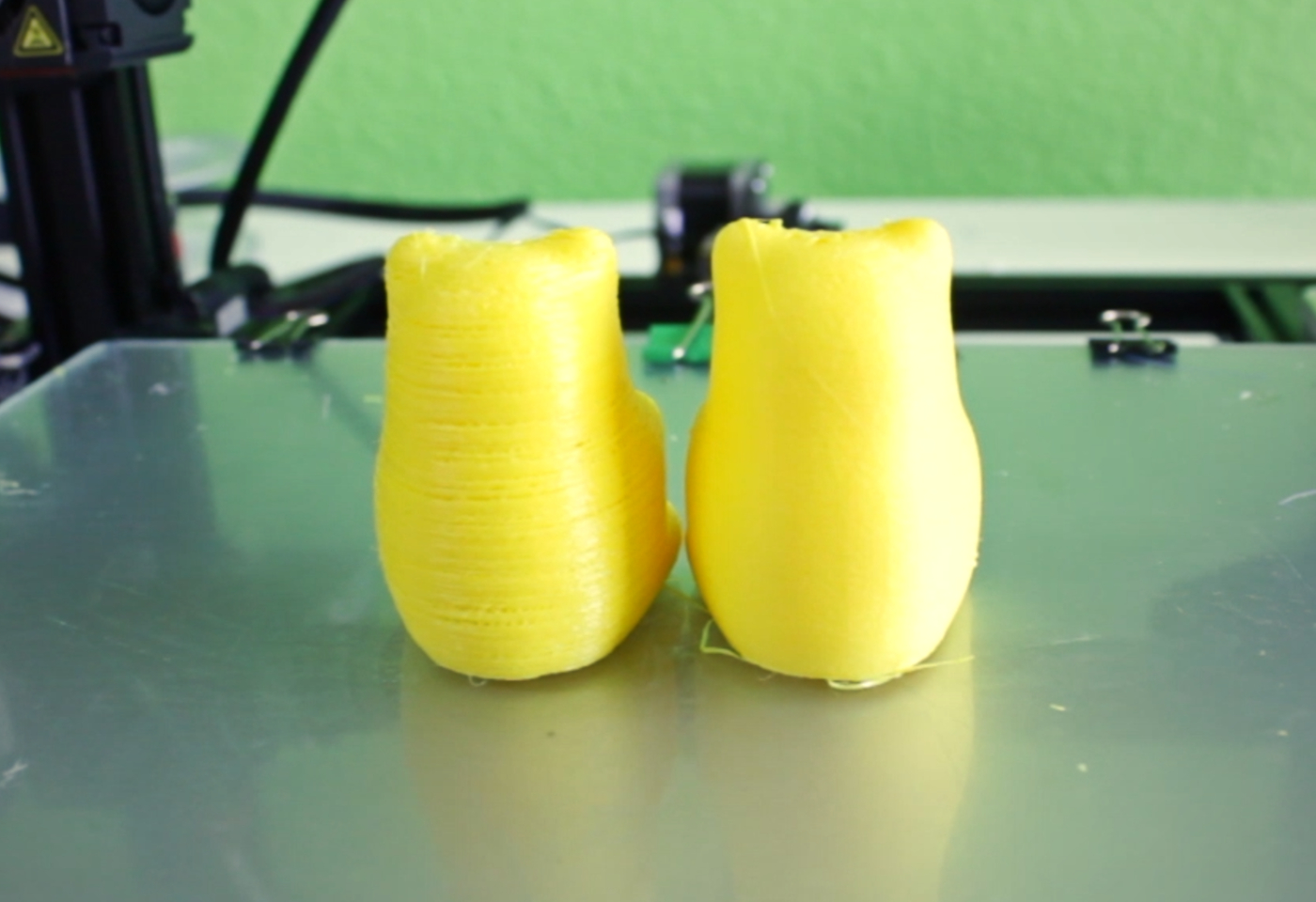

Sometimes your printed pieces do not have the quality and finish that you were looking for? And also, ever, when printing with Filaflex, does your printer’s filament extrusion flow come out poor or intermittent?

If so, it could be due to a partial blockage in the extruder nozzle of your printer due to sediment remains from other filaments. And the good news, a problem that we can avoid and correct quickly and easily!

To solve it, we will have to proceed with its repair and cleaning. It is a process that we recommend to be carried out from time to time as a necessary maintenance task to achieve an optimal extrusion flow in our prints.

Find out why it is important to maintain and repair the hotend of your 3D printer and the steps you must follow to be able to do it quickly and easily.

de

de  es

es en

en fr

fr it

it