Learn with Recreus

3D printing enthusiasts folks, today December 3rd (3D) we celebrate the INTERNATIONAL 3D PRINTING DAY!

After more than 30 years since the invention of the first 3D printer, this day strives to raise awareness, educate and promote the benefits of the 3D printing industry or Additive Manufacturing, as it is also known.

A technology that has been a huge boost to industry and society, creating and manufacturing new innovative and revolutionary opportunities.

Brief history of 3D printing

To know the history of 3D printing, we must first take into account several relevant milestones that marked its beginning.

- 1976 - The inkjet printer is invented. With the appearance of these first 2D printers, the desire to go one step further was born: to move from the object that is in a machine and comes out drawn on paper, to print it physically.

- 1981 - The Japanese Hideo Kodama invents two methods of plastic manufacturing with a polymer that hardens under ultraviolet light.

- 1984 - Frenchmen Alain Le Méhauté, Oliver de Witte and Jean Claude André file their patent for the stereolithography process. And they do so just three weeks before Chuck Hull files his own patent for stereolithography. Eventually the Frenchmen's application would be abandoned for 'lack of business perspective' while Chuck Hull, co-founder, executive vice president and chief technology officer of 3D Systems, would invent stereolithography, the first commercial rapid prototyping technology, creating the first 3D printed part in history.

10 chronological milestones in the history of 3D printing

.jpg)

1984

Chuck Hull develops the 1st 3D printing technology: stereolithography.

1985

Autodesk’s CAD software offers 3D modeling for the first time.

2002

At the Wake Forest Institute the 1st miniature and functional kidney is 3D printed.

2005

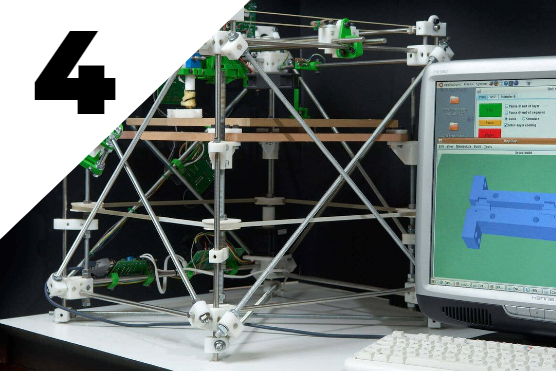

RepRap is founded, it is the first self-replicating manufacturing machine. An open source initiative that aims to build a 3D printer that can print most of its own components.

2006

A Material Jetting printer is created, the 1st machine to print multiple materials at the same time.

2011

Engineers at Southampton University 3D print and fly the first UAV (unmanned aerial vehicle).

.jpg)

2013

Filaflex is born, the first elastic and flexible filament for 3D printing manufactured by Recreus :)

2014

Local Motors develops the first partly 3D printed electric car, Strati.

2018

A family moved into the first habitable 3D printed house in Nantes, France.

.jpg)

2019

At Tel-Aviv University, the 1st functional tiny human heart in the world is 3D printed.

And what else has happened since then?

After these milestones that have marked 3D printing technology, we cannot forget some other important, and very recent, events that have happened in these last two years.

- 2020 - With the outbreak of the Covid-19 pandemic, 3D printing technology becomes a clear savior and demonstrates its full potential and value. It helps by producing and manufacturing quickly and from anywhere the necessary materials in the face of an apocalyptic scenario of crisis and scarcity of resources in health protection materials.

- 2021 - Very recently, news broke that a patient in the United Kingdom received the world's first 3D printed ocular prosthesis. A breakthrough in manufacturing and innovation in time and realism. Traditional acrylic prosthetic eyes are hand-painted and take about six weeks to complete. With 3D printing, once a scan has been taken, the prosthesis can be printed within two and a half hours. It is then sent to an ocularist to finish polish and fit. The whole process takes just two to three weeks.

.

And what's next? What we are sure of is that 3D printing technology has no limits and is booming. Undoubtedly, it has all the potential to continue surprising us and revolutionize many more sectors and industries that need a change to improve and become more sustainable and/or efficient.

Source: 3D Natives and Wikipedia.

de

de  es

es en

en fr

fr it

it