Not Just PLA: 6 reasons why PETG filament is worth printing with

Since the beginnings of 3D printing, PLA (polylactic acid) filament has established itself as the undisputed leader and has become the most widely used material in 3D printing, due in part to its price and ease of printing. A material that lacks competition when it comes to creating quick and simple prototypes, and that is chosen and preferred by everyone when we need to print from any printer due to its great compatibility.

But what if out of habit or lack of information we are missing out on the opportunity to try other alternative materials to PLA filament that could potentially be much more interesting and attractive for our 3D prints?

Well, indeed, without a doubt, among others, there is the great forgotten and magnificent PETG filament. A filament that has everything and is not exploited at all. It lacks the fame and fortune of PLA filament, despite having many more qualities.

But don't despair! Below we give you the 6 reasons why you should change your mindset and start betting right now on printing with this material.

We'll tell you all about it!

Industrial machine pistons being printed with Recreus' navy blue PETG.

What is PETG filament?

PETG filament is a 3D printing material composed of polyethylene terephthalate (PET) and glycol (G) added to it. This results in a less brittle filament that is easier to use in 3D printing.

It has emerged as one of the most versatile and reliable options for 3D printing parts.

"If a 3D print has to withstand high temperatures and mechanical demands, standard PLA filament is not sufficient due to its low heat resistance. This is where PETG comes in. Compared to PLA, it is more temperature-resistant, more chemical-resistant, and can withstand greater mechanical loads. Another fairly unknown advantage is its low emission processing. Unlike PLA, it produces up to five times less gases and fine particle emissions, so hardly any odor is noticeable during processing."

Manuel Strauss from TechStage.de

1 | DURABLE AND RESISTANT

The PETG filament has extraordinary mechanical properties comparable to ABS. Among them, we can highlight:

- Durability: PETG is a very strong and durable material that can last a long time without losing its mechanical properties, ensuring that printed objects can withstand daily use and wear. Its hardness and impact resistance make it ideal for creating functional parts and prototypes, and for printing parts that need to be flexible but also strong. A perfect balance between strength and flexibility.

- Impact resistance: PETG has high impact resistance, which means it can absorb shocks without breaking.

- Temperature resistance: PETG is a very temperature-resistant material and can withstand high temperatures without deforming.

- Tensile strength: meaning it can withstand a significant amount of weight and is less prone to breaking under tension thanks to its strong layer adhesion.

- Flexibility: it is a very flexible material and can be bent and twisted without breaking. This makes it ideal for printing parts that need to be flexible, such as hinges or joints and/or printed models that need to be assembled and snap-fit.

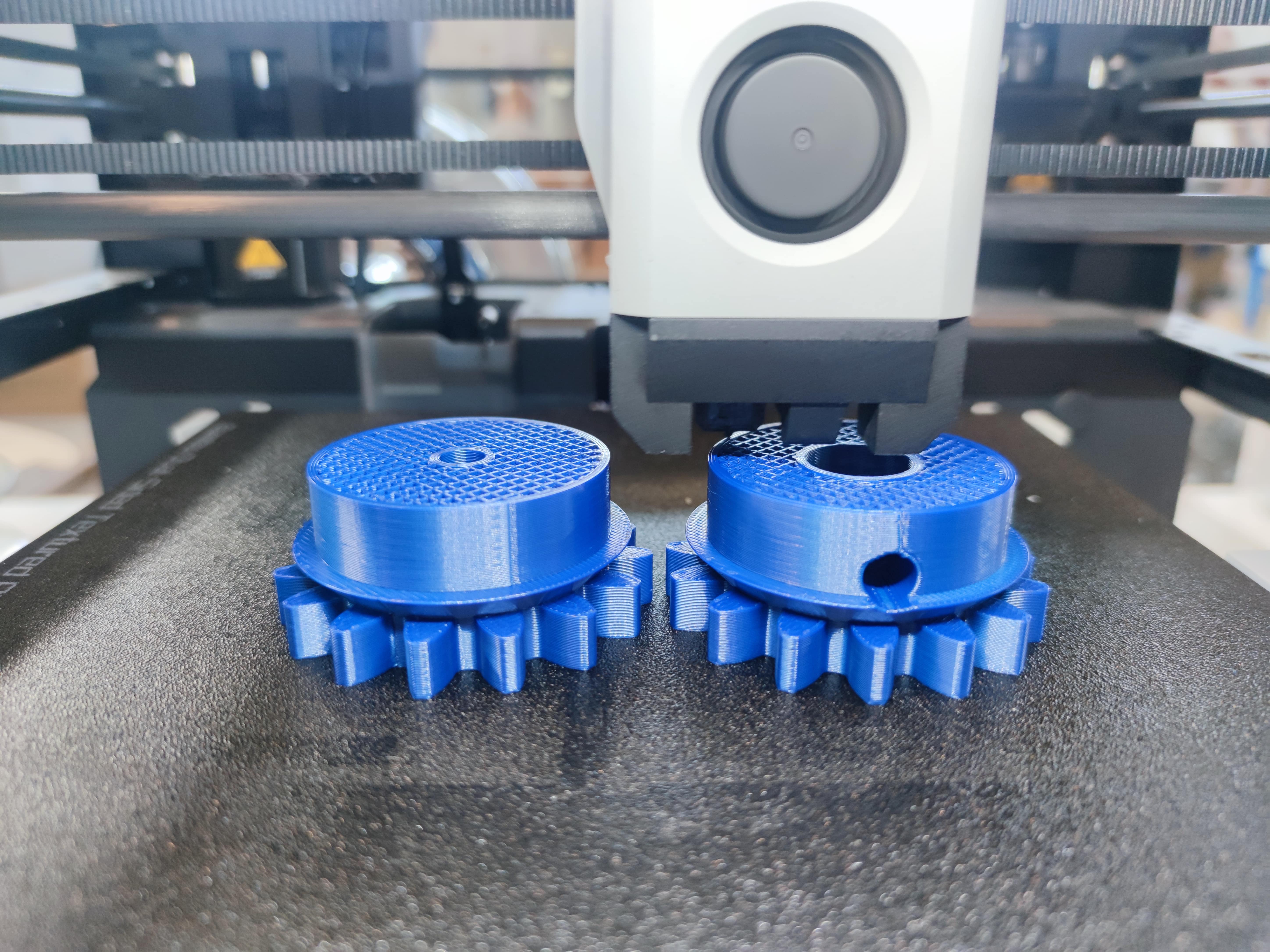

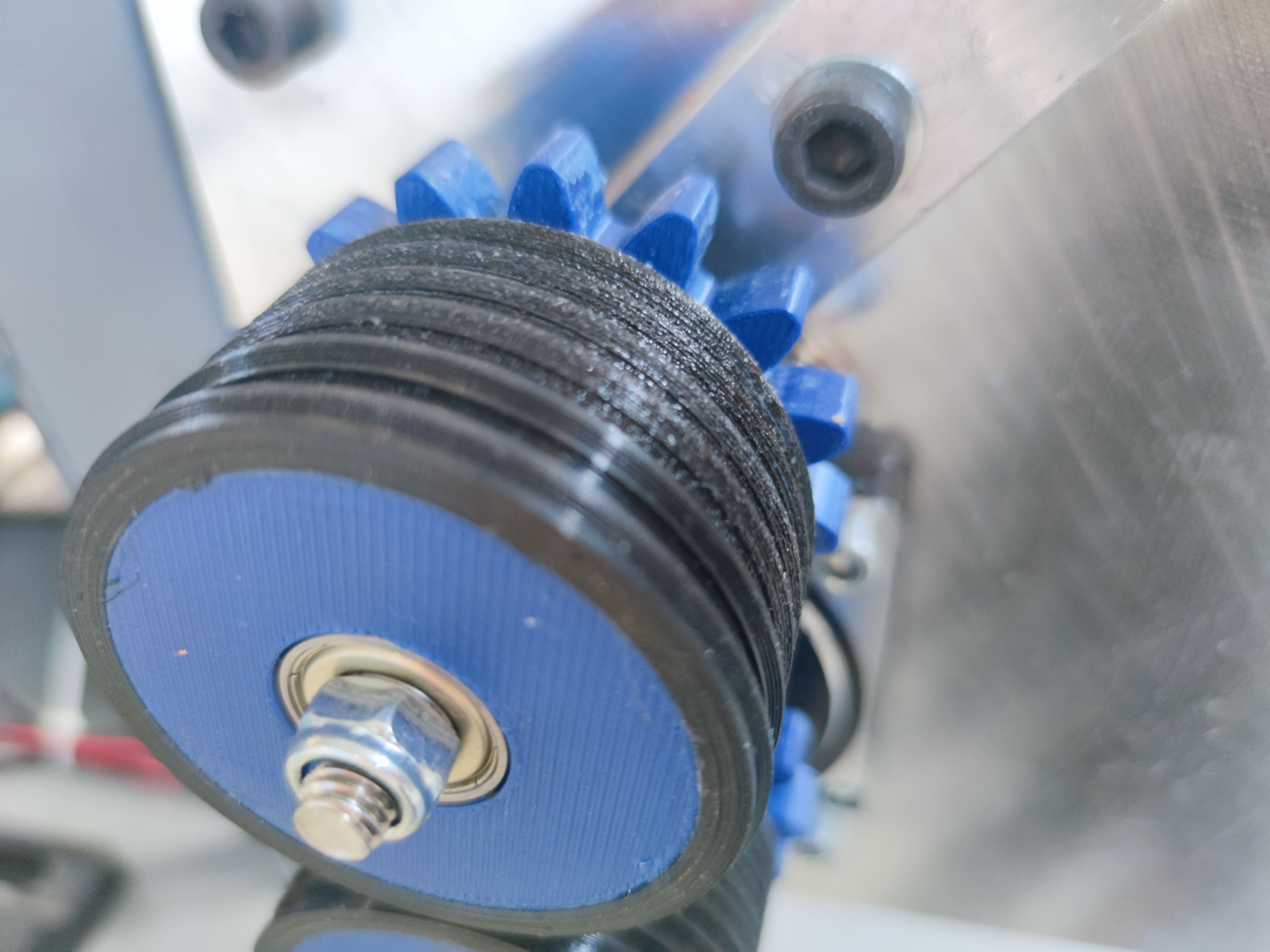

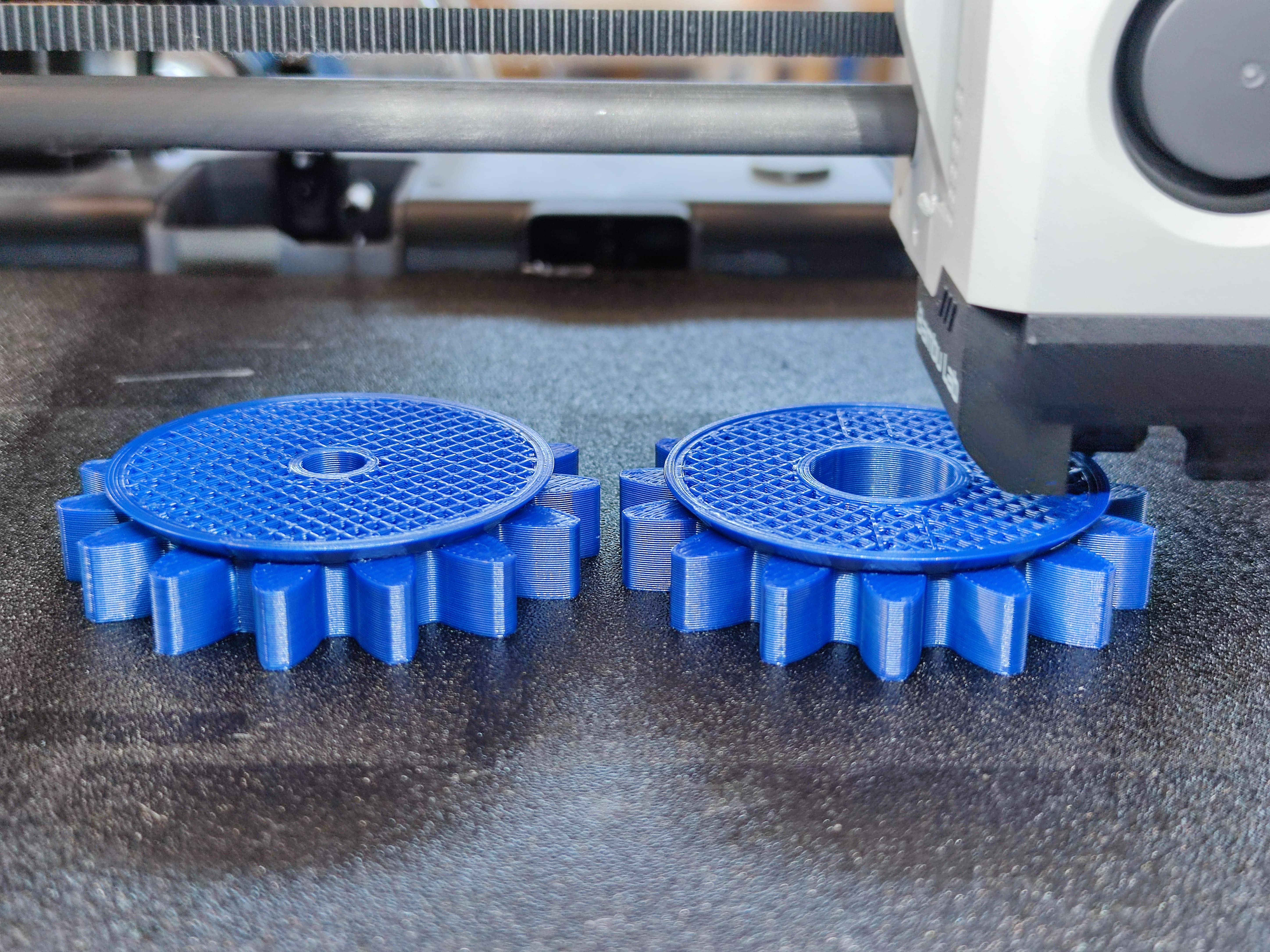

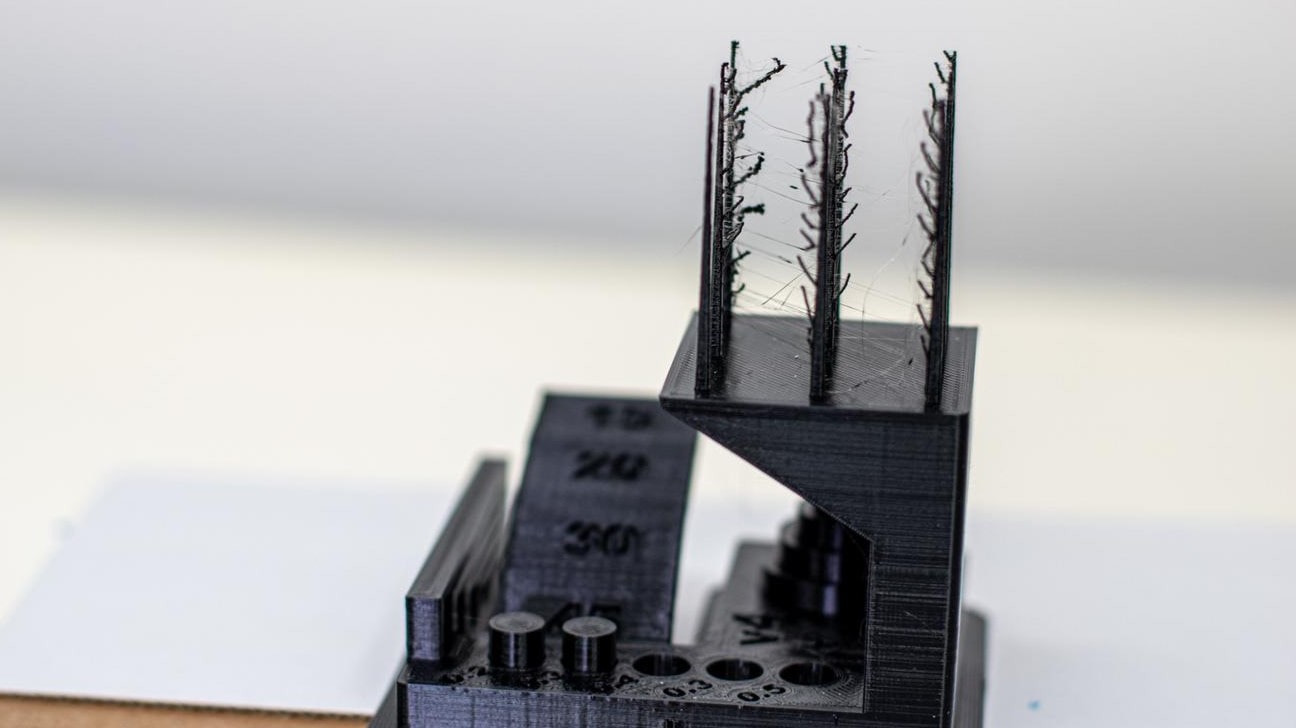

Thanks to its strength and durability, PETG filament is perfect for manufacturing technical and/or industrial parts. In this case, a component has been printed using navy blue PETG filament to integrate it into industrial machinery.

2 | EASY TO PRINT

PETG filament is known for its ease of printing. In fact, it is as easy to print as PLA.

It has excellent bed adhesion and minimal deformation, which reduces the chances of printing failures and the 'warping' effect.

With a relatively low printing temperature (ranging from 230-260°C), PETG filament provides an optimal range of compatibility with most FDM 3D printers.

This makes it an excellent choice for both beginners and experienced users in 3D printing.

The PETG filament adheres perfectly to the printing bed.

3 | HIGH CHEMICAL RESISTANCE

The PETG filament has good chemical resistance in general.

It is resistant to many common chemicals, such as alcohols, diluted acids, oils, and fats.

Due to its chemical resistance, it can be used to create parts that come into contact with any type of solvent, adhesive, or chemical agent.

An example of this is a successful case where PETG filament is used to 3D print a part that fits inside the lid of a container. This allows for a brush to be attached and creates a container lid with an applicator for a liquid adhesive.

.jpg)

PETG filament can be used to create parts that come into contact with solvents or adhesives due to its chemical resistance.

4 | ODORLESS AND NON-TOXIC

Unlike ABS, PETG filament is an odorless material with lower emission of fumes during printing, making it suitable for use indoors and in areas with poor ventilation. It's a healthier, less toxic, and more eco-friendly option.

.jpg)

We can print parts inside without the need for ventilation. It is not a toxic filament and does not give off odors like other types of 3D printing filaments.

5 | EXCELLENT FINISH

The PETG filament is known for its impressive finish thanks to its magnificent layer adhesion.

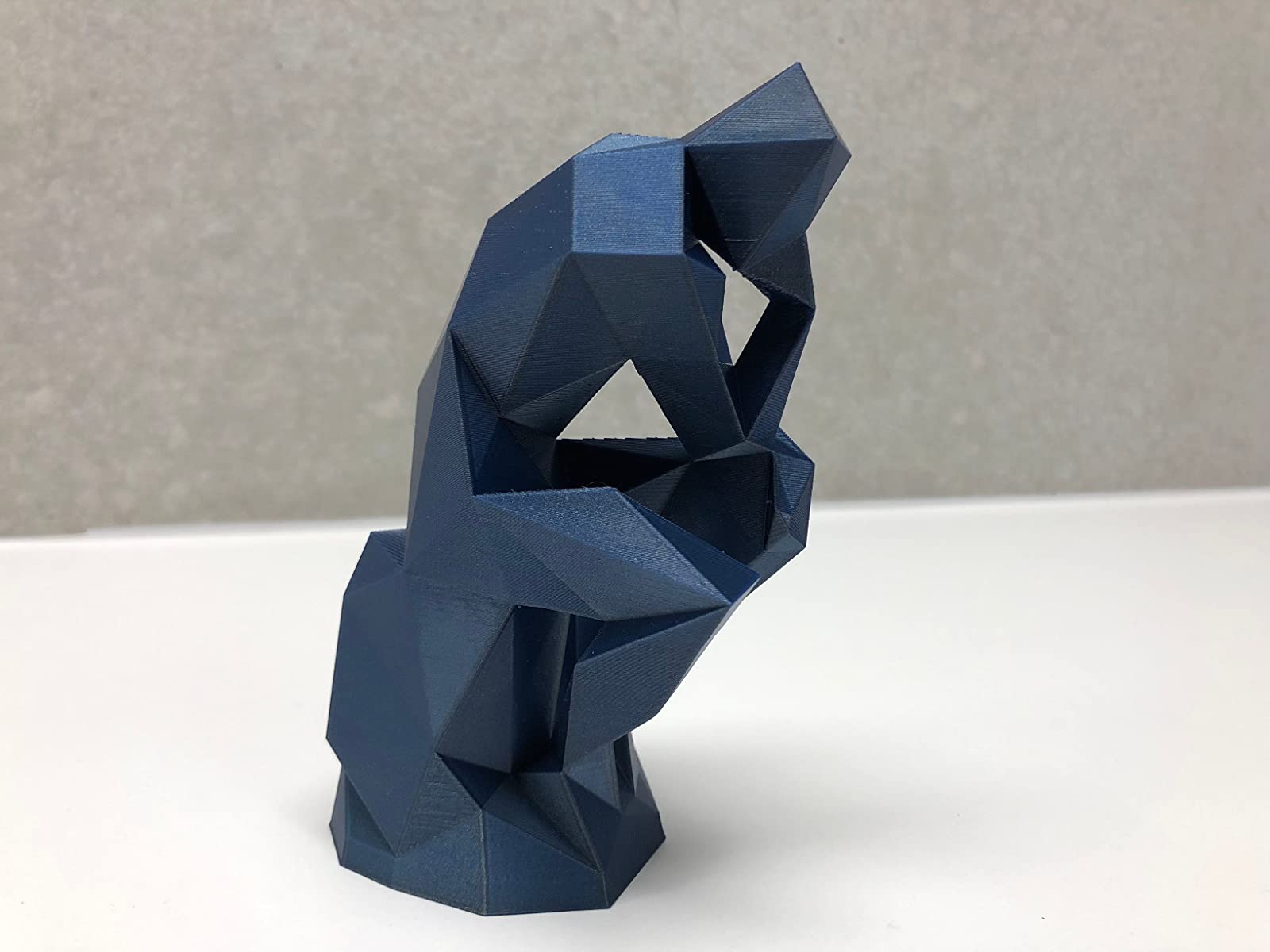

In general, the finish of pieces printed with PETG filament is usually smooth and shiny, with an appearance similar to that of injection molded plastic. Objects and final pieces can be manufactured with a very good final finish.

PETG filament has a very good finish.

6 | THE HIGHEST RATED

If there weren't already enough reasons to use PETG filament for your prints, we now give you one more reason to choose Recreus PETG.

Recreus PETG filament is the highest rated and has received the highest score in a comparative test ranking conducted by Manuel Strauss of the German technology media TechStage.

-min.jpg)

Image: TechStage.de

Below you can see photos of printed pieces for the test with our PETG filament.

To see all the details of the comparative test and read the full article, access from here.

Image: TechStage.de

Image: TechStage.de

Image: TechStage.de

Image: TechStage.de

Image: TechStage.de

fr

fr  es

es en

en de

de it

it