PPGF

Polypropylene filament with glass fiber is a composite material that combines the properties of both materials. The result is a filament that is easy to print, light, resistant to wear and tear as well as bending and tensile strength, with very good interlayer adhesion and low shrinkage deformation.

- €49,90 EUR

- €49,90 EUR

- Unit price

- per

Couldn't load pickup availability

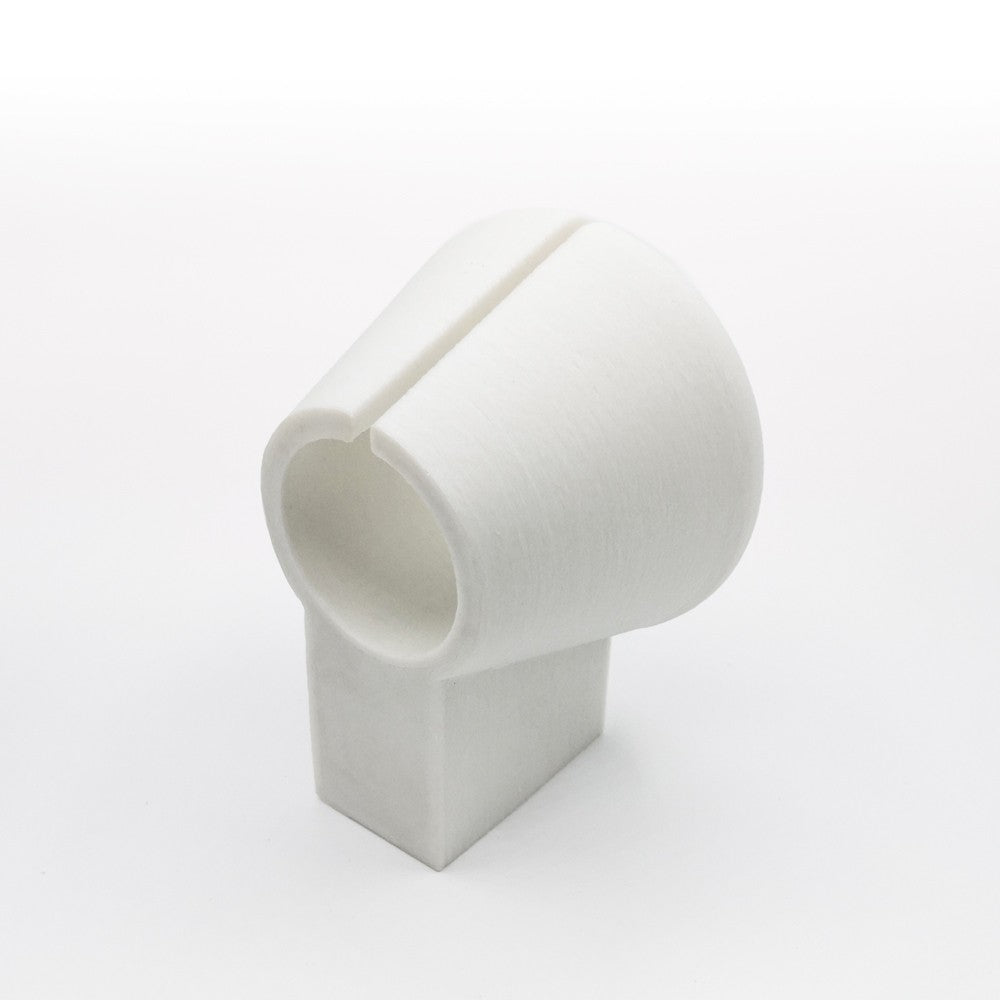

PP·GF (Glass Fiber Polypropylene), developed in collaboration with Repsol, represents a breakthrough in engineering-grade 3D printing materials. This composite filament combines lightweight polypropylene's corrosion resistance with glass fiber's exceptional tensile and flexural strength. The result is a high-performance material that delivers superior mechanical properties and durability, featuring a smoother finish than conventional glass fiber products.

Engineered for demanding applications, PP·GF offers outstanding chemical resistance, structural integrity, and impact resistance. Each spool comes with a specialized adhesion primer for optimal bed adhesion, ensuring reliable prints across multiple applications. The material's unique combination of flexibility and strength makes it ideal for functional parts that require both durability and precision in industrial environments.

Key Features

- Enhanced Strength: Superior tensile and impact resistance Industrial

- Chemical Resistance: Excellent durability against corrosion

- Premium Finish: Smoother surface than standard GF materials

- Versatile Properties: Balanced flexibility and rigidity

- Complete Solution: Includes adhesion primer for optimal results

Professional Applications

- Automotive: Panels, fenders, and protective components

- Industrial: Machinery parts and gear housings

- Marine: Fuel tanks and storage compartments

- Sports Equipment: High-performance gear components

- Hydraulics: Pump rotors, fittings, and nozzles

Complete Technical Printing Guide - PP-GF (Glass fiber)

🌡️ 1. Material Preparation

Filament Drying (CRUCIAL):

- 📏 Temperature: 50°C

- ⏱️ Minimum time: 4-6 hours

- 💡 Proper drying is essential for optimal printing results and to prevent moisture-related issues

⚡ 2. Understanding Print Speed

Volumetric vs. Linear Speed

- 🌊 Volumetric Speed (mm³/s): Like water through a hose - measures how much plastic flows per second, regardless of nozzle size.

- 📏 Linear Speed (mm/s): Like walking speed - how fast the printer head moves across the print area

- 🔑 Key Formula: Linear Speed = Volumetric Speed / (Line Width × Layer Height)

✨ The Magic: When you set a volumetric speed limit in your slicer, it automatically calculates and adjusts all linear speeds (perimeters, infill, etc.) based on your current nozzle size and layer height. This ensures consistent material flow regardless of your print settings!

⚙️ 3. Basic Parameters

Unique Characteristics of PP-GF

Glass Fiber reinforced Polypropylene (PP-GF) combines the chemical resistance of PP with enhanced dimensional stability and reduced warping thanks to its glass fiber content. This material offers improved mechanical properties, better dimensional accuracy, and reduced thermal expansion compared to standard PP3D.

| Nozzle | Layer Height | Line Width | Volumetric Speed | Temperature |

|---|---|---|---|---|

| 0.4mm | 0.2mm | 0.42mm | 4.5 mm³/s | 245°C |

| 0.6mm | 0.3mm | 0.62mm | 14.6 mm³/s | 247°C |

| 0.8mm | 0.4mm | 0.82mm | 25.9 mm³/s | 250°C |

| 1.0mm | 0.5mm | 1.02mm | 40.5 mm³/s | 253°C |

🚀 4. Speed Settings

⚠️ NOTE: Due to the glass fiber content, lower speeds are recommended compared to standard PP3D to minimize wear and ensure proper layer adhesion. These speeds are calculated based on the volumetric flow rates for optimal fiber orientation and layer bonding.

0.4mm Nozzle (Volumetric Speed: 4.5 mm³/s)

| Line Type | Percentage | Speed |

|---|---|---|

| External Perimeter | 50% | 26.79 mm/s |

| Internal Perimeters | 75% | 40.18 mm/s |

| Infill | 100% | 53.57 mm/s |

| Top/Bottom | 60% | 32.14 mm/s |

| First Layer | 30% | 16.07 mm/s |

0.6mm Nozzle (Volumetric Speed: 14.6 mm³/s)

| Line Type | Percentage | Speed |

|---|---|---|

| External Perimeter | 50% | 39.25 mm/s |

| Internal Perimeters | 75% | 58.87 mm/s |

| Infill | 100% | 78.49 mm/s |

| Top/Bottom | 60% | 47.10 mm/s |

| First Layer | 30% | 23.55 mm/s |

0.8mm Nozzle (Volumetric Speed: 25.9 mm³/s)

| Line Type | Percentage | Speed |

|---|---|---|

| External Perimeter | 50% | 39.51 mm/s |

| Internal Perimeters | 75% | 59.27 mm/s |

| Infill | 100% | 79.02 mm/s |

| Top/Bottom | 60% | 47.41 mm/s |

| First Layer | 30% | 23.71 mm/s |

1.0mm Nozzle (Volumetric Speed: 40.5 mm³/s)

| Line Type | Percentage | Speed |

|---|---|---|

| External Perimeter | 50% | 39.71 mm/s |

| Internal Perimeters | 75% | 59.56 mm/s |

| Infill | 100% | 79.41 mm/s |

| Top/Bottom | 60% | 47.65 mm/s |

| First Layer | 30% | 23.82 mm/s |

↩️ 5. Retraction Settings

🚀 IMPORTANT: Due to the glass fiber content, PP-GF requires slightly lower retraction speeds compared to standard PP3D to minimize filament abrasion and prevent grinding. The fiber content also helps reduce stringing, allowing for shorter retraction distances.

| Nozzle | Distance | Speed | Z-Hop |

|---|---|---|---|

| 0.4mm | 0.8-1.2mm | 25mm/s | 0.2mm |

| 0.6mm | 0.8-1.2mm | 25mm/s | 0.2mm |

| 0.8mm | 0.8-1.2mm | 25mm/s | 0.2mm |

| 1.0mm | 0.8-1.2mm | 25mm/s | 0.2mm |

Additional Retraction Recommendations:

- Minimum Travel for Retraction: 1.5mm

- Maximum Retraction Count: 100

- Minimum Extrusion Between Retractions: 1mm

- Retract on Layer Change: Yes

- Wipe Before Retraction: Yes

- Use hardened steel nozzle to prevent wear from glass fiber

- Monitor retraction settings and adjust if excessive stringing occurs

🌡️ 6. Bed Temperature Settings

Print Surface Requirements:

- Recommended surface: Clean glass bed + PP3D Primer

- First Layer Temperature: 40°C with PP3D Primer

- Removal Temperature: 85°C

- Chamber Temperature (if available): Room temperature with no drafts

How to Use Recreus' PP3D Primer

Step-by-Step Application Guide:

- Open PP3D Primer bottle

- Apply directly to print area

- Ensure even coverage

- Wait minimum 5 minutes

- Allow primer to dry completely

- Avoid touching prepared surface

- Set bed temperature to 40°C

- Maintain this temperature during printing

- Do not exceed 40°C to prevent deformation

- After print completion, heat bed to 85°C

- Remove part carefully

- Let bed cool before next application

- Clean residue with Sanytol or acetone

- Store primer bottle tightly sealed

- We recommend to use a dedicated buildplate for Polypropylene printing

Step 1 - APPLY

Step 2 - DRY

Step 3 - HEAT

Step 4 - REMOVE

Cleaning & Maintenance

❄️ 7. Cooling Settings

Cooling Configuration:

- First Layer: 0% (fan off)

- General Printing: 0% base fan speed

- Layers < 9 seconds: 30% fan speed

- Minimum Layer Time: 10 seconds

- Keep Fan Always On: OFF

- Force Fan Speed for Overhangs: OFF

- Bridge Fan Speed: 30%

- Maximum Fan Speed: 30%

- Minimum Layer Time: 10 seconds

- Maximum Layer Time: 30 seconds

- Lift Head on Layer Too Fast: Yes

- Glass fiber content helps with thermal stability

- Minimal cooling required for optimal layer adhesion

- Only use cooling for bridges and overhangs

- Enclosed chamber highly recommended for this material

- Temperature consistency is crucial for fiber orientation

Base Fan Settings:

Advanced Settings:

Layer Time Goals:

Critical Considerations for Glass Fiber:

🔧 8. Troubleshooting Guide

| Problem | Solution |

|---|---|

| Poor Bed Adhesion | 1. Clean build plate thoroughly 2. Reapply fresh PP3D Primer 3. Verify bed temperature is exactly 40°C 4. Increase first layer width (110%) 5. Reduce first layer speed |

| Warping | 1. Use enclosure if possible 2. Eliminate all drafts 3. Ensure fan is OFF for first layers 4. Add brim or raft 5. Verify proper primer application |

| Under-extrusion | 1. Increase printing temperature by 5°C 2. Check for partial nozzle clog 3. Reduce print speed 4. Verify filament is dry 5. Increase flow rate by 2-3% |

| Stringing | 1. Fine-tune retraction settings 2. Ensure filament is properly dried 3. Optimize travel moves 4. Enable z-hop for travel moves 5. Lower printing temperature 2-3°C |

| Layer Separation | 1. Increase printing temperature 2. Reduce cooling fan speed 3. Lower print speed 4. Check for drafts 5. Ensure proper layer height |

| Rough Surface Finish | 1. Check for moist filament 2. Reduce printing temperature 3. Optimize retraction settings 4. Slow down outer perimeter speed 5. Verify nozzle condition |

Common PP3D-GF Print Issues Prevention:

- Always store PP3D-GF in airtight container with desiccant

- Pre-heat filament at 50°C for 1-2 hours if stored improperly

- Regular maintenance of nozzle and print surface

- Check bed leveling before each print

- Monitor first layer adhesion carefully

✨ 9. Best Practices

- Reinforced hardness steel nozzle for abrasive materials

- Clean glass bed (recommended) or dedicated buildplate for Polypropylene Printing

- PP3D Primer (essential)

- Enclosed chamber (recommended)

- Standard brass nozzle (suitable)

- Direct drive or bowden setup (both compatible)

- Store in sealed bag with desiccant

- Keep humidity levels below 40%

- Avoid direct sunlight exposure

- If needed, dry at 50°C for 1-2 hours

- Handle spools carefully to prevent tangling

- Always use fresh PP3D Primer application

- Level bed while at printing temperature

- Start with small test prints

- Print first layer slower for better adhesion

- Use brim for larger parts

- Enable Z-hop for travel moves

- Allow parts to cool completely before removal

- Heat bed to 85°C for easy part removal

- Clean build plate between prints

- Remove support structures with the help of heatgun(recommended)

🛠️ Hardware Requirements

🌡️ Material Care

⚙️ Print Setup

🎯 Quality Optimization

🔬 Post-Processing

⚠️ IMPORTANT NOTE: PP3D-GF is an engineering-grade material that requires proper handling and printing conditions. While it's forgiving compared to other engineering materials, following these best practices will ensure optimal print quality and part performance. Always perform test prints before critical productions.

Related Products

- from €49,90 EUR

- from €49,90 EUR

- Unit price

- per

- from €49,90 EUR

- from €49,90 EUR

- Unit price

- per

- from €49,90 EUR

- from €49,90 EUR

- Unit price

- per

- from €49,90 EUR

- from €49,90 EUR

- Unit price

- per

- from €49,90 EUR

- from €49,90 EUR

- Unit price

- per

- from €49,90 EUR

- from €49,90 EUR

- Unit price

- per

- from €49,90 EUR

- from €49,90 EUR

- Unit price

- per

- from €49,90 EUR

- from €49,90 EUR

- Unit price

- per

- from €49,90 EUR

- from €49,90 EUR

- Unit price

- per

- from €49,90 EUR

- from €49,90 EUR

- Unit price

- per

Latest Posts

Filaflex: The Perfect Flexibility for Custom Orthopedics

PLA Purifier: The innovative material that cleans the air while creating sustainable products

Filaflex 70A in one of the components of EYEDAK's new 'vrAse 2' VR device

Recently Viewed Products

- from €49,90 EUR

- from €49,90 EUR

- Unit price

- per

- from €49,90 EUR

- from €49,90 EUR

- Unit price

- per

- from €49,90 EUR

- from €49,90 EUR

- Unit price

- per

- from €49,90 EUR

- from €49,90 EUR

- Unit price

- per

- from €49,90 EUR

- from €49,90 EUR

- Unit price

- per

- from €49,90 EUR

- from €49,90 EUR

- Unit price

- per

- from €49,90 EUR

- from €49,90 EUR

- Unit price

- per

- from €49,90 EUR

- from €49,90 EUR

- Unit price

- per

- from €49,90 EUR

- from €49,90 EUR

- Unit price

- per

- from €49,90 EUR

- from €49,90 EUR

- Unit price

- per

- Choosing a selection results in a full page refresh.