3D printing has revolutionized the field of medicine and orthopedics, offering innovative and personalized solutions for a wide range of medical needs. In this article, we will explore how Clara Soriano, a specialist in orthopedics and custom footwear design, has used Filaflex flexible filaments to create high-quality, customized, and biocompatible orthopedic products. Discover why she has chosen Filaflex as the ideal material for manufacturing all her custom orthopedic devices!

3D printed insole with Filaflex to help treat sesamoiditis

3D Printing and Medicine

A Success Story with Filaflex

ORME | Custom Orthopedics

Company: ORME. It is a project born from the passion of its founder, Clara, for two seemingly different worlds: orthopedics and product design. After years of experience in both fields, she decided to join forces to address a need that often went unnoticed: the lack of customized products to meet very technical and specific needs in people and animals.

As she puts it, "I don't make mass-produced products. I design custom solutions for individual lives."

Material: Filaflex 82A and Filaflex 95A.

Product: Custom orthopedic devices.

“I choose your filaments for the quality they offer, combining the strength, flexibility, and biocompatibility I seek in materials, as well as being easy to print and usable on a cold bed. My first experience with flexible filaments was with Filaflex 82A, and I was pleasantly surprised by the excellent results. As I tried other brands, it became clear to me that I would stick with yours.”

Clara Soriano, Founder of ORME

Manufacture of Custom Shoe Soles

Custom footwear with soles printed in Filaflex

"To manufacture the soles of our custom footwear, we use flexible filament Filaflex 82A and Filaflex 95A, depending on the design characteristics and the patient's needs. With custom footwear, we always aim to respect the natural movements of the foot and allow the patient to exercise the intrinsic muscles of the foot. Occasionally, we introduce corrective elements if it's necessary to modify the biomechanics of the gait or add stabilizing components. However, the general objective of custom footwear is to protect the foot while allowing it to develop and move freely."

Clara Soriano, Founder of ORME

Flexible and soft soles printed with Filaflex

"The advantages offered by using Filaflex flexible filament for the soles lie in its characteristic property of flexibility without deformation. We often play with densities to create areas of greater and lesser cushioning, to optimize the total weight of the product and offer a comfortable walking experience."

Clara Soriano, Founder of ORME

Fully flexible soles printed with Filaflex for footwear that is respectful and comfortable for the feet

Custom Insole Production

Insole printed with flexible Filaflex filament

"For insoles, we typically blend Filaflex 82A for areas requiring more rigidity, such as supporting the inner foot arch, aligning the heel, or implementing similar corrective features, and Filaflex 60A for components focused on redistributing pressure in more sensitive regions. The notable benefit of utilizing these materials over traditional resins, foams, or silicones lies in their longevity; elements crafted with Filaflex are built to last, aligning with our sustainability commitment. While insole linings may require periodic replacement, the active core remains intact, maintaining its original properties without loss of density or deformation from wear or patient weight. This represents a significant step forward and a key advantage, both in treatment efficacy and in combating planned obsolescence."

Clara Soriano, Founder of ORME

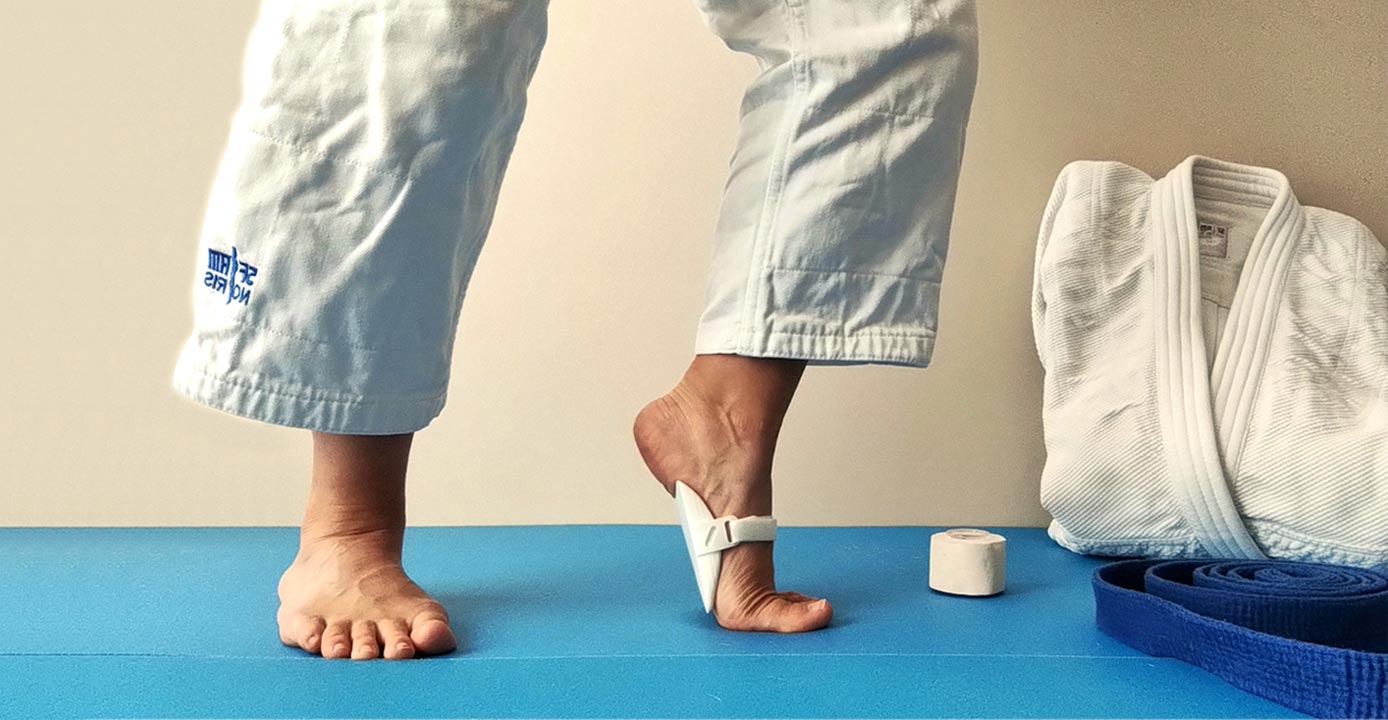

Insole printed with flexible Filaflex filament for practicing Judo

Manufacturing of Immobilization Splints

3D Printed Splint with Filaflex for Treating Finger Arthritis

3D Printed Splint with Filaflex for Treating Dupuytren's Disease

"When it comes to crafting our splints, we rely on Filaflex 95A. While polypropylene is the usual choice for such applications, it tends to present numerous printing hurdles, particularly with adhesion (I'm still looking forward to testing your PP3D). Filaflex 95A typically provides the necessary rigidity to immobilize a joint. In instances where it falls short, we either blend it with a stiffer material or beef up the splint's thickness. Additionally, we utilize Filaflex 82A for the closures on our splints. We offer a diverse range of closures tailored to match the specific characteristics of the condition and the patient's preferences, ranging from Velcro straps to colored rings and buckle straps. The breadth of closure options is extensive, especially in veterinary products, where an animal's knack for removing items plays a significant role; some can practically disrobe themselves of anything."

Clara Soriano, Founder of ORME

A 3D printed splint made with Filaflex to immobilize the wrist, suitable for water exposure

“Another advantage of using Filaflex Flexible filament is its biocompatibility, meaning the material can be in contact with healthy skin. In many cases, we line the applications, especially those for the foot, like insoles, but for finger or hand splints, it's very useful to be able to do without the lining, as this allows the patient to come into contact with water without having a material that takes a long time to dry or may cause skin problems due to excess moisture."

Clara Soriano, Founder of ORME

3D-printed Filaflex brace for dog's knee

3D-printed Filaflex orthosis for Haglund's syndrome

3D-printed Filaflex orthosis for Haglund's syndrome

“Filaflex 82A flexible filament has been the least troublesome material for me after PLA filament. It's easy to print without needing too many adjustments or extensive testing of flow, temperature, and retractions. The quality and flexibility it provides are ideal for the applications I require. Moreover, its ease of printing is comparable to that of stiffer materials or those with properties more akin to a higher shore TPU filament. However, these other options, while easy to print, don't offer the mechanical characteristics that Filaflex does."

Clara Soriano, Founder of ORME

Splint being printed with flexible Filaflex filament on the Witbox 2 printer

it

it  es

es en

en fr

fr de

de