Learn with Recreus

Debunking the myths about 3D printing with flexible filament or TPU. We help you and solve all your doubts!

I read that printing flexible filament is very difficult. I think it's not for me

Nothing could be further from the truth! It is neither more difficult nor easier, it is simply different from printing with other types of materials that you are used to.

The most important thing is to know your printer. Know if it is direct extrusion or Bowden and the type of extruder it has, if it is all-metal or incorporates a PTFE tube along the entire length of the hotend. All this will determine the Shore of the flexible filament, such as Filaflex, with which you will be able to print.

In fact, more and more competitively priced desktop printers are being launched on the market that print and work very well with flexible filament.

However, if you need help and support to get started, we will always guide and advise you quickly on the filament that best suits your needs and printer. In addition, on our website you will find a wide range of learning content that you can consult whenever you want to successfully print our flexible filaments, such as Filaflex.

Are there different types of flexible filament?

Certainly, taking into account their Shore hardness. Within the flexible filament or TPU family we can find a wide variety of TPUs that we can classify according to their 'Shore hardness'. Shore hardness is a very important parameter that helps us to determine the elasticity of a flexible filament. For example, in our range of Filaflex flexible filament we have different Shore hardness of this material: 60A, 70A, 82A or 95A. So we can talk about the same filament, but with different behaviors based on their elastic properties. Here we talked about this concept in more detail - don't miss it!

Actually, I don't know which filament of the 4 Filaflex Shore hardnesses I should use. Filaflex 82A, Filaflex 95A, Filaflex 70A or Filaflex 60A?

In this case, try them and decide! In fact we have available a sample pack of 50gr. each, which you can check here, which includes the 4 Filaflex Shore hardnesses. It is the perfect pack to test the different elasticities of the filament and thus assess which is the most suitable for your project, before buying a larger spool. However, as always, we will be happy to help and advise you.

I think Filaflex 82A filament is the right filament for what I'm looking for, but could I try it before buying a spool?

Of course! You have two sample packs of Filaflex 82A available, a monochrome pack with 4 basic colors, such as black, white, transparent and gray, and another pack with the colors red, blue, yellow and green. This way you can test the filament for your safety before buying a larger spool.

I don't know which flexible filament is the most suitable for my project.

If despite everything you have read, you are still not sure which filament is the most suitable for your needs and your printer, contact us at info@recreus.com and we will advise and help you without any obligation.

Is Filaflex safe for skin contact?

Indeed! Filaflex is a material that is compatible with skin contact at the cutaneous level, is non-toxic and does not generate odors. Filaflex has been used and is still used to create many applications such as textile parts and accessories, as well as insoles and prostheses that are in contact with the skin. However, it should not be introduced intracutaneously (inside the skin) and is not recommended for use in wounds or bedsores without performing the appropriate toxicological tests for the application in question.

Is Filaflex skin contact and food contact certified?

Our production, storage, preparation and delivery process complies with good manufacturing practices regulations. In addition, we have a letter of conformity available upon request, indicating the products and colors in the Filaflex range that use raw materials that comply with European standards and FDA regulations.

Regarding the certificate, this must be done on the final product that is printed with Filaflex. It is a responsibility to be assumed by the agent who introduces it on the market according to the transformation process and its specific use.

What 3d printer can I use to print Filaflex 60A and 70A?

In general, the basic premises for printing with these filaments, as well as with Filaflex 82A, are that the printer has to be a direct extrusion printer and the hotend doesn't has to be all-metal. Having clarified this, the printers that work well with these Shore hardnesses are:

With Filaflex 70A

- Artillery Genius and Sidewinder X1

- Anycubic Predator

- Creality CR-10, Ende-3 and Ender-3 Pro

- Printrbot

- Sovol Sv01

- Ultimaker 2+ ,S3 and S5 (consult with our team)

- WitBox 2

With Filaflex 60A

- Artillery Genius and Sidewinder X1

There are probably many more, but these are the ones that we know work, either from our customers' feedback or from our own experience.

I have read that it is not recommended to print flexible filament on bowden 3d printer extruders. Could I print Filaflex with my bowden extruder?

It is more complicated to print flexible filament with a bowden extruder because the material must be pushed from the spool to the extruder through the entire printer tube (remember the saying "you can't push a rope").

What can I do to print flexible filament on my bowden extruder printer?

First of all, it depends on the Shore hardness of the flexible filament you want to print. In the case of the Filaflex range, Filaflex 95A filament is compatible with this type of extruders and you will have no problem printing with it.

With respect to Filaflex 82A, to be able to print this lower and softer hardness, the tube will have to be made of PTFE. With this low friction material you will prevent the filament from sticking to the inside of the tube and will allow a better flow of the filament.

For printing softer Filaflex Shore hardnesses, such as 70A and 60A, it will be much more difficult and we do not recommend it and it will depend on many other factors.

To learn more about bowden extruder printers and printing with flexible filament, please learn more here.

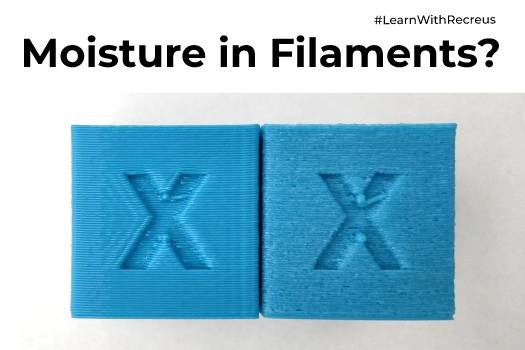

I am printing with my spool of flexible filament, but the finish is not quite right and the surface looks a bit lumpy, what can it be due to?

95% of the time it is usually a moisture problem that is quickly solved by drying the spool before printing. Although Recreus carries out exhaustive quality management processes in the production of our filaments, in order to ensure that they do not absorb any moisture, it is inevitable that the filament may absorb some moisture once it is received by the customer. Therefore, we recommend to keep or store the spools out of any atmosphere susceptible to moisture.

However, to improve the finish of your piece and remove moisture from the spool, you have several options. From using a filament dryer or a food dehydrator, to the more rudimentary and conventional method that consists of introducing the coil in your oven at a temperature of 50ºC in fan mode for 3 hours. You can consult here more information about ‘Moisture vs. flexible filaments’.

And don't forget, whatever your question is, and, if unfortunately we have not already solved it in this section, or even in the FAQs section (which you can access from the 'Support' section of the main menu of this website), we will be delighted to hear from you through our email info@recreus.com in order to solve all your doubts and questions.

it

it  es

es en

en fr

fr de

de