Filaflex 82A

TPU Filament Filaflex 82A, 'Original', is the star elastic filament of the Filaflex range. The best-selling and most popular flexible filament for 3D printers.

- Shore hardness 82A

- 650% stretch

- High elasticity

- Odourless

- No hotbed required

- Made in the EU

TPU filament Filaflex 82A, 'Original', is a TPU (thermoplastic polyurethane) elastic filament with a shore hardness of 82A, capable of reaching up to 650% stretch before breaking. Thanks to its elastic property, this flexible filament returns to its original shape without deforming or breaking after stretching.

Filaflex TPU filaments are characterized by their great adhesion to the printing bed, so they do not require a heated bed, blue tape, kapton tape, lacquer or any other adhesive spray. In addition, they are odorless and resistant to certain types of solvents and fuels.

Printing Filaflex 82A TPU filament requires different guidelines than rigid filaments. Therefore, the 3D printer must be properly configured. For proper operation, we recommend printing on direct extrusion 3D printers.

The TPU filament Filaflex 82A is the most popular and commonly used TPU for 3D printing. It is the flagship flexible filament of the Filaflex brand and a great ally for 3D printing flexible parts.

Applications

Filaflex 82A TPU filament is non-toxic and can be in contact with the skin. Consult for medical or food use. It can be used to create:

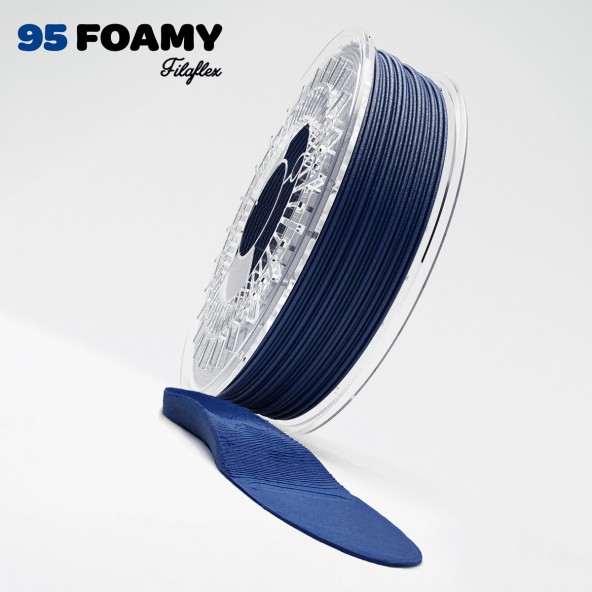

– Insoles: orthopaedic insoles.

– Prosthesis and organ models: prosthetic arms, hands, organs for simulation of surgical operations,...

– Flexible objects and parts for industry, automotive: buffers, gaskets, tires, grippers ...

– Textile parts and accessories: textile garments, fabrics, printing on garments, bags, earrings,...

- Printing temperature

- 215-250°C.

- Print speed

- 20-60 mm/s.

- Diameter tolerance

- 0.03 mm.

- Layer height

- 0.2 mm.

- Retraction speed

- 40 mm/s at a distance of 4-6 mm. In the extreme case of an extruder jam, disable retractions.

- Tips

- Increase the flow if the extrusion of the filament is intermittent, between 105% - 115%, and reduce the pressure of the lever arm that presses the filament on the motor pulley, to avoid strangling the filament and producing jams.

- Shore hardness

- 82A

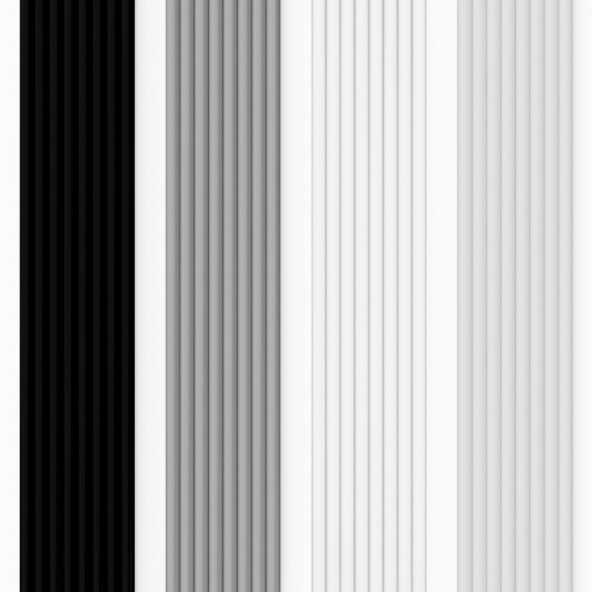

Filaflex 82A various colors

After printing 20+kg of filaflex 82A over a few years it is safe to say it's an excellent filament. Never experienced any faults that weren't process related.

As with all flexibles that I have tried it is a more challenging print process the softer you go. I have pushed limits and scrapped well over 5kg of prints made in Filaflex 82A. My experience spans from printing on cheap open bedslinger systems to more refined enclosed systems. Nozzles I have used are 0,4, 0,6 and 0,8mm. The general rule is that the printing needs to be slow, and very slow if the designs have any form of overhangs.. The overhangs want to curl up, and if that starts it only gets worse. It helps to run larger nozzles for both process stability and part strength.

This filament needs to be well dried for printing, so I nowadays print directly out of an active dryer to avoid any such problems.

My impression is that Ninjaflex 85A is slightly softer than Filaflex 82A despite the numbers saying otherwise.

I find that 95A filaments in general seldomly are flexy or "rubbery/grippy" enough when a flexy part is needed. By tuning the shell and infill parameters a wide range of softness can be achieved with this 82A filament.

The pictured play car design is a paid model that can be seen at the below link. The 4 tyres, the seat and the dampening bodies in the shock absorbers are all printed from Filaflex 82A with very good results. Suitable softness for the application and very durable.

https://www.printables.com/model/1023623-breezebuggy-a-high-performance-ride-on-play-car-fo

The 240mm diameter rear tyres designed for the car are free to download on the below link and fit standard 6,5" hoverboard motors. Filaflex 82A has been a good filament to create maintenance free tyres that provide grip and ride comfort for the application.

https://www.printables.com/model/1026957-off-road-tyres-for-65-hoverboard-motors-240mm-od

1st print TOP

Hi... This product is great... 1st print with Recreus settings is very good, So easy to setup ! Better than any flexible tried before on my Raise Pro 2

Einfach nur genial!

Ich bin sehr zufrieden mit dem Filament! Es war genau das was ich gesucht habe. Zwar war die richtige Einstellung für meinen Drucker nicht einfach zu finden, doch irgendwann ist der Knoten geplatzt. Ein Cura Profil sowie ein paar Bilder zum Filament habe ich auf YouTube hochgeladen. https://youtu.be/1vNHmw6b-3I

One of the best TPU filament

You have found the best name for this product; simple to describe the type (Fila_ment flex_ible) & easy to remember . To printing with your filament since fews year ago now, we can said that one of the best Tpu filament we have trying with direct drive and bowden extruder ??

gb

gb  es

es fr

fr de

de it

it

It's what I've been looking for

I now own 7 different colors. Very cool filament, and a PHENOMENAL color selection :)