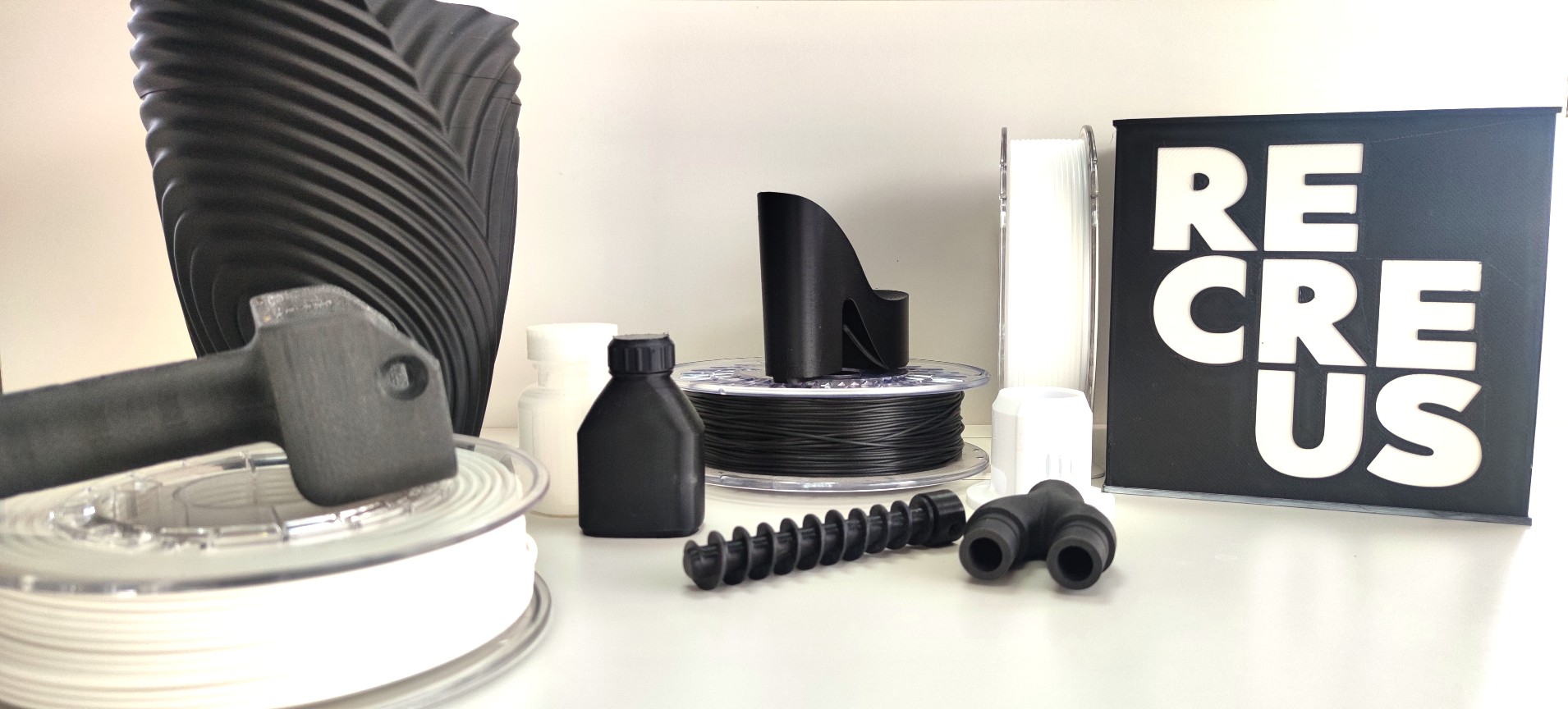

Recreus technical filaments for 3D printing

The technology of 3D printing has revolutionized the way we design and manufacture objects, becoming, in certain cases, a great alternative to injection molding. This technology, combined with the application of materials and filaments with exceptional mechanical properties, has become a powerful source of alternative and competitive manufacturing that covers numerous production needs in any industry sector. Thanks to the advantages that 3D printing offers, such as reduced production time, low cost, precision, quality, and accessibility, among many other things, it offers great benefits in the following cases:

- Manufacturing replacement parts for machines. Manufacturing machine spare parts with 3D printing helps reduce their breakdown or downtime, in addition to eliminating waiting times for the reception of spare parts from the supplier.

- Possibility of customizing or manufacturing company machines or production systems without large investments. If the machine that the company needs does not exist in the market or its price is too high, why not manufacture it? You can design and manufacture your own machine or solution for your business at a low cost and in record time, or even modify your existing machinery to adapt it to other functions.

- Possibility of manufacturing limited editions or short runs of customized products. Sustainability, exclusivity, immediacy, or personalization, there is an increasing demand for products with these characteristics. Responding to this demand is profitable and competitive thanks to 3D printing technology. Short runs of a specific product can now be manufactured at a low cost, allowing for its viability in the market and for the company.

But, if we add to the advantages of this technology, the development and innovation of materials and filaments for printing, 3D printing has the potential to further revolutionize the manufacturing industry, and alternatives and possibilities can multiply.

That's why at Recreus, as developers and manufacturers of filaments for 3D printing, we have been working on creating these materials, with an extensive portfolio of 3D printing filaments designed to meet the demands of any technical and industrial project. Innovative filaments for 3D printing on another level, designed to go one step further in the most challenging projects and developments in the industry.

Discover in this list the variety of materials that our team has developed for multiple technical options and applications. An extensive catalog where you can compare properties and see which materials may be the most suitable for your project. Don't settle for the obvious or the easy when creating and go one step further. Discover this wide selection of technical filaments for 3D printing!

PP·3D | Polypropylene

What is PP Filament for 3D Printing?

Polypropylene filament is a flexible material that can be bent and twisted without breaking. It's popularly used in the automotive, packaging, and medical industries due to its chemical, moisture, and impact resistance. For 3D printing, PP filament offers a range of advantages, including flexibility, chemical resistance, and water resistance:

- Flexibility: PP filament is flexible and can be used to print objects that need to be bendable, such as hinges and moving parts.

- Chemical resistance: PP filament is resistant to many chemicals, making it ideal for printing objects that will be in contact with chemicals.

- Water resistance: PP filament is resistant to moisture and water, making it a popular material for printing products that will be in contact with liquids and require tightness. You can use it to print bottles and packaging, both functional prototypes and final-use products.

Key points of PP·3D polypropylene from Recreus

Recreus PP-3D is an advanced polypropylene filament that is high impact, chemical resistant, durable and very easy to print. It features exceptional fatigue resistance and high levels of toughness. It has a low coefficient of friction and is non-toxic. Its finish is impressive, similar to injection molding, which makes the appreciation of the bond between layers disappear, resulting in a piece of very high quality and exceptional finish.

Recreus PP-3D incorporates a fixing primer to be applied on the printer bed before printing to avoid the dreaded warping and achieve maximum adhesion at only 40ºC (on a glass table).

- Chemical resistant

- Easy to print

- Autoclavable

PP·GF | Polypropylene Glass Fiber

What is polypropylene fiberglass filament?

Polypropylene filament with glass fiber (PP GF) is a material composed of two materials, polypropylene and glass fiber. Polypropylene, on the one hand, is a thermoplastic polymer commonly used in the manufacture of packaging and textile products, while fiberglass is a strong and durable material used in the construction industry.

In 3D printing, polypropylene filament with fiberglass is used to create objects that require high strength and durability, such as machine parts, automotive prototypes and aircraft parts. The combination of polypropylene and fiberglass allows 3D printed objects to be stronger and more durable than objects printed with other materials.

Among the advantages that stand out of this material, we can find:

- Tensile strength. Polypropylene filament with fiberglass is very resistant to traction, which makes it ideal for creating objects that require high strength, such as machinery parts and automotive parts.

- Compressive strength. Polypropylene filament with fiberglass is also very resistant to compression, making it ideal for creating objects that must withstand heavy weights or pressures, such as aircraft parts and heavy machinery parts.

- Temperature resistance. Polypropylene filament with fiberglass is able to withstand high temperatures, making it ideal for creating objects that must withstand high temperatures, such as machinery parts that are used in high-temperature environments.

- Corrosion resistance. Polypropylene filament with fiberglass is highly resistant to corrosion, making it ideal for creating objects that will be used in corrosive environments, such as machinery parts used in the chemical industry.

Key points of Recreus PP·GF glass-fiber reinforced polypropylene

Recreus' PP-GF glass fiber polypropylene filament PP-GF has been developed in collaboration with the multinational Repsol. This union has improved the strength and durability characteristics of this material, making it an ideal choice for applications that require a high level of mechanical resistance.

- Resistant to moisture and corrosion

- High mechanical and flexural strength

- Good chemical resistance

- Suitable for high temperatures

- Low density

- High wear resistance

PPGF

PET-G

What is PET-G filament for 3D printing?

PET-G filament, also known as thermoplastic copolyester, is a 3D printing material composed of polyethylene glycol (PET) and terephthalic acid. It is a thermoplastic polymer that can be molded by heat and pressure, making it ideal for use in 3D printers.

In the 3D printing industry, PET-G filament has become a popular and versatile material. Its high strength and durability make it ideal for a wide range of applications, from engineering parts to decorative objects.

PET-G filament is a very strong, durable and flexible material. It has high impact strength and is resistant to thermal deformation, which means it retains its shape even at high temperatures. It is also UV-resistant, which makes it ideal for outdoor applications. In addition, PET-G is a non-toxic and recyclable material, making it an environmentally friendly material, which is highly desirable at this time.

There are several advantages to using PET-G filament for 3D printing. Some of them are:

- Durability. PET-G is a very strong and durable material that can withstand high tensile loads without breaking.

- Flexibility. Unlike other materials, PET-G is flexible and does not break easily, making it ideal for parts that need a bit of flexibility.

- Low shrinkage. PET-G has minimal shrinkage during printing, which means that printed parts do not deform easily.

- UV resistance. PET-G is UV resistant, making it ideal for outdoor applications.

- Recyclable. PET-G is a recyclable material, making it environmentally friendly.

Key points of Recreus PET-G

Recreus PET-G filament is a rigid filament that has outstanding mechanical properties comparable to ABS, with no harmful vapors, and is as easy to print as PLA. In addition, it is resistant to high temperatures and is a durable and resistant material.

Its adhesion properties between layers, its non-emission of odors and its high resistance to chemical agents (solvents, acetone,...), make it the ideal material for printing technical and industrial parts. You will get parts with a glossy finish, forgetting cracking or warping problems.

- Ideal for technical and industrial parts

- High chemical resistance

PET-G

PET-G CF | PET-G Carbon Fiber

What is PET-G CF filament for 3D printing?

PET-G CF filament is a combination of PET-G and carbon fibers. This combination provides excellent strength and stiffness, along with the ease of PET-G printing. Carbon also provides improved tensile strength and stiffness, making it ideal for printing mechanical and structural parts.

PET-G CF filament is commonly used in the manufacture of mechanical and structural parts, where high strength and stiffness are required. It is ideal for printing aerospace, automotive and sports parts. It is also used in the manufacture of prototypes and high precision parts.

Among the advantages that can be highlighted of this material, we find:

- High strength and rigidity

- Ease of printing

- Improved tensile strength

- Low weight

- Excellent dimensional stability

Key points of Recreus PET-G CF

PET-G CF is the result of a filament that combines the optimal mechanical properties of Recreus PET-G filament with the strength, stiffness and lightness of carbon fiber (10%). It has an elastic modulus three times higher and a breaking strength 5 times higher than conventional PET-G. A very powerful combination of materials that achieves a material resistant to wear and impact and with high resistance to heat and low temperatures.

To print PET-G CF we recommend using hardened steel or ruby type nozzles, avoiding brass nozzles that tend to erode easily. With PET-G CF you will be able to obtain final parts with high mechanical resistance and a matte black finish.

- Excellent mechanical properties

- Impact and wear resistant

- Chemical resistance

- High thermal resistance

- High toughness and low density

- Ductility

- Good interlayer adhesion

- Compatible with most 3D printers

- Matte black finish

PET-G CF

PLA-LW | PLA Light Weight

What is PLA-LW filament for 3D printing?

PLA-LW or PLA LIGHT WEIGHT is a PLA variant that is characterized by being much lighter than conventional PLA. In addition to its light weight, PLA-LW also offers other interesting properties for 3D printing. This material is resistant to deformation, which makes it ideal for printing parts that require high precision. In addition, PLA-LW is easy to print and does not require a heated bed for bonding.

The main difference between conventional PLA and PLA-LW is the latter's light weight. While conventional PLA has a density of about 1.24 g/cm³, PLA-LW can have a density as low as 0.6 g/cm³. This property makes PLA-LW ideal for printing parts that need to be lightweight, such as those used in the aerospace industry.

The main advantages of this material are:

- Lightweight. The lightness of PLA-LW is its main advantage compared to conventional PLA. This property makes the filament ideal for printing parts that need to be lightweight, such as those used in the aerospace industry.

- Strength. Despite its low density, PLA-LW is a material that is resistant to deformation. This property makes it ideal for printing parts that require high precision.

- Biodegradability. PLA-LW is one of the few 3D printing filaments that is biodegradable and environmentally friendly. This material is produced from corn starch and other biodegradable materials, making it more sustainable than petroleum-based filaments. In addition, PLA-LW does not emit toxic fumes during the printing process, making it safe for use in closed environments.

Key points of Recreus PLA-LW

PLA-LW (Light Weight) from Recreus is a lightweight PLA filament for 3D printing, which thanks to technology of active foaming reduces the flow during extrusion of the part to 50% or 60% maintaining the same line width and thus reduces the weight of the part. In addition, with the effect of the foaming we can achieve the layers of the part to blend, achieving an exterior finish that is much more uniform.

PLA-LW filament is ideal for creating lightweight, low-density, yet strong parts. By reducing the flow in the printing of this material, we can print up to two or three times more parts than with a conventional PLA spool. A clear example of the application of PLA-LW is in the manufacture of model airplanes.Thanks to the foaming of the material at high temperatures we can reduce the total weight of the model and therefore reduce the wing load of the aeromodeller enabling an improvement in its flight qualities. Another example is in the use of material when making complements or accessories for ‘cosplay’, as they will be lighter and more bearable.

- Light weight

- Low density

- Material that spreads farther

- Easy to print

- Resistant and less brittle

- Great surface finish

- Matt finish

PLA-LW

Conductive Filaflex

What is conductive flexible filament for 3D printing?

Conductive flexible filament for 3D printing is a material that combines the properties of electrical conductivity and flexibility, making it ideal for creating parts that need both properties. This material can be used to manufacture objects that need to be bent or flexed, such as sensors, medical devices and wearables.

The conductive flexible filament for 3D printing is composed of a mixture of conductive and non-conductive materials, which allow electricity to flow through the filament to make it conductive. On the other hand, the non-conductive material ensures that the filament is flexible and can bend without breaking.

Conductive flexible filament for 3D printing has a wide range of applications in different fields.

- Sensors and medical devices. Conductive flexible 3D printing filament is ideal for creating medical sensors and devices, as it is flexible enough to conform to the shape of the human body and conductive enough to measure the body's electrical activity.

- Wearables. Wearables, such as smartwatches, need sensors that can measure the body's electrical activity.

- Toys and robotics. Conductive flexible 3D printing filament is also used in the creation of toys and robots, as it enables the creation of complex parts that need to be flexible and conductive. For example, it can be used to create the joints of a robot or the electrical wires of a toy.

- Electronics and technology. Flexible conductive 3D printing filament is used in the creation of electronic components, such as antennas and printed circuit boards. It can also be used in the creation of lighting devices, such as flexible LED lamps.

So with regard to its advantages, we can highlight:

- Electrical conductivity

- Flexibility

- Possibility of creating complex parts

- High precision in printing

Key points of Recreus Filaflex Conductive

Filaflex Conductive is a flexible electrically conductive TPU filament with a 92A shore hardness, designed for the manufacture of electrically conductive parts or components and ideal for the creation of wearable devices. Thanks to its 92A shore hardness, it is compatible with 90% of 3D printers on the market. It offers two of the most coveted properties in 3D printing: flexibility and conductivity.

- 92A Shore hardness

- Flexible and conductive

Conductive Filaflex

Filaflex SEBS

What is SEBS flexible filament for 3D printing?

SEBS flexible filament is a 3D printing material characterized by high flexibility and tensile strength. SEBS stands for "styrene-ethylene-butylene-styrene", which is a type of thermoplastic polymer used in the manufacture of rubber products. This material is a thermoplastic elastomer that can be printed on a 3D printer and enables the creation of parts with flexible and soft properties.

SEBS flexible filament is used in a wide variety of applications, from the creation of toys and engineering parts to the manufacture of medical and textile parts. Due to its high flexibility, SEBS flexible filament is ideal for creating parts that require a high degree of elasticity, such as gaskets, hoses and fasteners. In addition, this material is also abrasion and corrosion resistant, making it a popular choice for manufacturing parts that must withstand harsh conditions.

It is important to note that SEBS flexible filament requires a 3D printer with a specialized nozzle and extruder designed to work with flexible materials.

Among its advantages, we can highlight:

- High flexibility and tensile strength

- Abrasion and corrosion resistance

- Ability to create complex parts

Recreus Filaflex SEBS key points

Recreus Filaflex SEBS flexible filament is a strong and durable TPE rubber-based material that can flex and bend back to its original shape and resist impact and fatigue. It is an ideal technical material for any industrial application. Due to its capacity and resistance to chemical and oxidizing agents, it can be used for outdoor applications and/or those that need to resist high temperatures, UV rays or rain, thanks to its impermeability. In addition, due to its water-repellent property, it is an ideal filament for 3D printing in high humidity environments. As for printing, it does not leave any threads and a high quality final piece is obtained in which its incredible ease when removing supports stands out.

Filaflex SEBS, due to its magnificent properties, is a perfect technical filament for industry and an alternative to PVC. Ideal for parts that need to dampen vibrations and / or retain their elastic properties even under exposure to high temperatures. It is also ideal for printing outdoor parts exposed to the elements.

- Flexible and elastic

- 90A Shore hardness

- Does not absorb moisture

- Waterproof

- Chemical resistant

- UV resistant

- Excellent soft-touch finish

- High level of detail

- Autoclavable

- Electrically insulating

- Easy support removal

- Easy to print on bowden machines

gb

gb  es

es fr

fr de

de it

it