Filaflex 60A

TPU Filament Filaflex 60A 'PRO' is the most elastic and flexible filament on the market for 3d printers. This filament is only suitable for the most experienced and daring 3d printing enthusiasts using flexible fialments.

- Shore hardness 60A

- 950% stretch

- Extremely elastic

- Odourless

- No hotbed required

- Made in the EU

TPU filament Filaflex 60A, the lowest Shore hardness of all the flexible filaments in the Filaflex range!

Once again, we've achieved it! We've manufactured the most elastic TPU flexible filament on the market for 3D printers with a breaking elongation of 950% and the lowest Shore hardness, 60A.

The flexible filament Filaflex 60A is positioned as the new member of the 'Filaflex' range, standing out for being the most elastic filament of all, with a Shore 'A' hardness of 60.

Like the rest of the flexible filaments in the range (Filaflex 70A, Filaflex 82A, and Filaflex 95A), Filaflex 60A 'PRO' has the property of elasticity. That is, after its stretching, Filaflex 60A returns to its original shape without deforming, as long as the elastic limit of the material is not exceeded.

The flexible filament Filaflex 60A 'PRO' is a highly flexible and elastic TPU filament only suitable for the most 'PRO', but NOT suitable for all-metal hotends of 3D printers, since the filament could become stuck and not flow properly. It is also not recommended to be printed on bowden type extrusion machines or 3D printers. However, if you have any doubt, please contact us for help or advice.

TPU filaments or flexible in the Filaflex range are characterized by having great adhesion to the printing bed. They do not require a heated bed, blue tape, kapton tape, lacquer, or any other adhesive spray. Additionally, they are odorless and resistant to certain types of solvents and fuels. Their printing requires different guidelines than rigid filaments. For this, 3D printers must be properly configured.

Applications

TPU Filament Filaflex 60A is non-toxic and can be in contact with the skin. Consult for medical or food use. It can be used to create pieces that require very high elasticity such as:

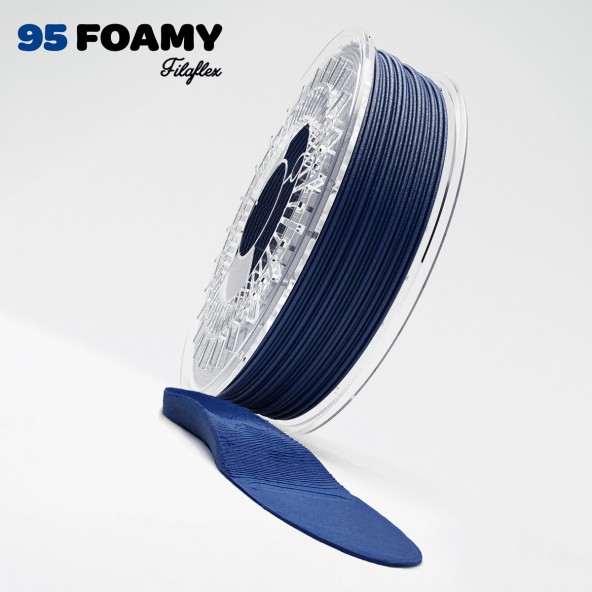

– Insoles: orthopaedic insoles.

– Prosthesis and organ models: prosthetic arms, hands, organs for simulation of surgical operations,...

– Flexible objects and parts for industry, automotive: buffers, gaskets, tires, grippers ...

– Textile parts and accessories: textile garments, fabrics, printing on garments, bags, earrings,...

- Printing temperature

- 215-225°C. 218°C recommended temperature (never approach or exceed 235°C).

- Print speed

- Start at 20mm/s and continue up to 40mm/s.

- Diameter tolerance

- 0.04 mm.

- Layer height

- 0,08-0,25 (for 0,4 mm nozzles). Optimal results 0,2 mm.

- Retraction speed

- 25 -30 mm/s at a distance of 2.5-6 mm.

- Travelling speed

- 160-200 mm/s.

- Shore hardness

- 60A

gb

gb  es

es fr

fr de

de it

it

Unique

Really enjoyed learning to work with this stuff. Once you master it, it really expands what you can do with 3-D printing via FDM. Anti vibration padding, gaskets, insoles, anti slide pads, living hinges and more. Print it slow (3mm/s bambu studio/ orcaslicer), 230c, and no heat on the bed. Retraction isn’t needed and you’ll want to back off the extruder tension spring. If you’re using a bambu lab printer, you’ll probably want to drill a hole in the housing so you can continue to loosen the tension screw the appropriate amount.