Filaflex 95A Pack

Sample pack of Filaflex 95A, which allows you to experiment and test the elasticity and Shore hardness with the best option in the Filaflex range to get familiar with TPU filament. With this sample pack of Filaflex 95A 'Medium-Flex', you can easily test and print the filament in various shades. You have two options, either choose the 'monochrome' pack, composed of the most popular monochromatic colors, or choose the 'colors' pack option if you want to try this filament in the most popular primary colors.

- Shore hardness 95A

- 500% stretch

- Medium elasticity

- Compatible with all printers

- Odourless

- No hotbed required

- Made in the EU

With this pack of four 50 g. samples of Filaflex 95A, you can test this elastic filament in your 3D printer without having to buy a larger spool. You have two packs available with two-colour combinations to choose from.

- The 'Monochrome’ Pack: composed of 4 samples of 50 gr. each one, in black (2 units), grey, white and transparent.

- The 'Colour’ Pack: composed of 4 samples of 50 g. each one, in red, green, yellow and blue.

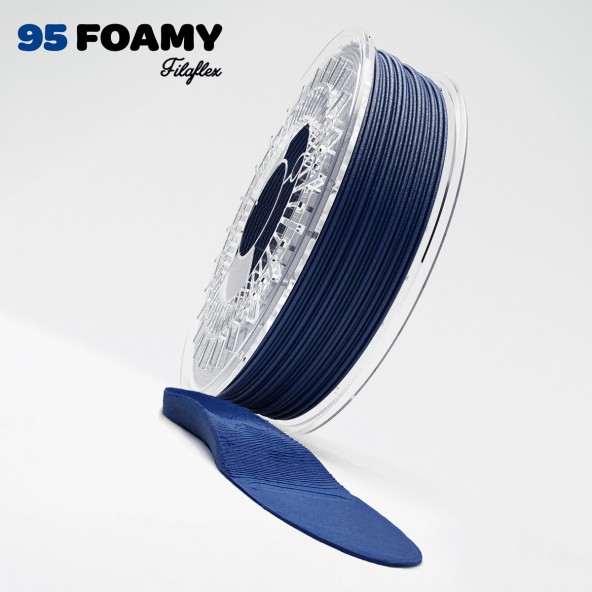

The Filaflex 95A, ‘Medium-Flex’, is a semi-flexible filament and, out of the entire Filaflex range, is the most compatible with all printers on the market, including those with a Bowden extruder (with tube). It has a 95A shore hardness, reaching up to 500% stretch before breaking. It's very easy to use and after stretching it returns to its original shape without deforming or breaking.

The filaments of the Filaflex range have great print bed adhesion, so they don't need a heated bed, blue tape, Kapton tape, lacquer or any other spray adhesive. What's more, TPU filaments are odourless and resistant to certain types of solvents and fuels. Its printing requires different guidelines to rigid filaments. That's why the 3D printer needs to be properly configured.

Applications

Filaflex 95A is non-toxic and can be in contact with the skin. Consult for medical or food use. It can be used to create:

– Insoles: orthopaedic insoles.

– Prosthesis and organ models: prosthetic arms, hands, organs for simulation of surgical operations,...

– Flexible objects and parts for industry, automotive: buffers, gaskets, tires, grippers ...

– Textile parts and accessories: textile garments, fabrics, printing on garments, bags, earrings,...

- Printing temperature

- 215-250°C.

- Print speed

- 20-70 mm/s.

- Diameter tolerance

- 0.03 mm.

- Layer height

- 0,08-0,3 (for 0,4 mm nozzles). Optimal results 0,2 mm.

- Retraction speed

- Direct Drive: 40 - 70 mm/s at a distance of 3.5 mm | Bowden: 40 mm/s at a distance of 6.5 mm.

- Travelling speed

- 160-200 mm/s.

- Shore hardness

- 95A

Summary

(0 Reviews)

gb

gb  es

es fr

fr de

de it

it